Used water-jet cutting equipment and machines for sale (42)

Darwen

Darwen Flow International 013659-2

Flow013659-2

Germany

Germany Waterjet Cutting Machine

STMWS3040

Mönchengladbach

Mönchengladbach Water jet cutting system

OMAXProtoMAX

+49 201 857 86 180

Sweden

Sweden Waterjet cutting machine

OMAXMAXIEM 2040

Barbing

Barbing Waterjet

CMS TecnocutEasyline 2040

Discover more used machines

Wien

Wien Water jet cutting system

PerndorferWSS4020

Haßloch

Haßloch Pump for waterjet cutting system

UhdeHPS 4011

Germany

Germany Waterjet Cutting Machine

H.G. RidderWaricut HWE 3020 2 2 D Retrofit

Austria

Austria Waterjet cutting machines

KK KletzerCNC 3 Achsen 3000 x 2000 x 250 mm

Sweden

Sweden Waterjet cutting machine

OMAXProtoMAX

Sonnenbühl

Sonnenbühl Water jet cutting system

Perndorfer

Schweiz

Schweiz Water Jet Cutting Machine

STMMasterCut

Skawina

Skawina Waterjet cutting machine

STMMasterCut V2 3020 2D

Poland

Poland Waterjet Cutting Machine

Waterjet ItalyCLASSICA CL 510

Austria

Austria Waterjet cutting machines

KK-IndustriesCNC 3 Achsen 4000 x 2000 x 250 mm

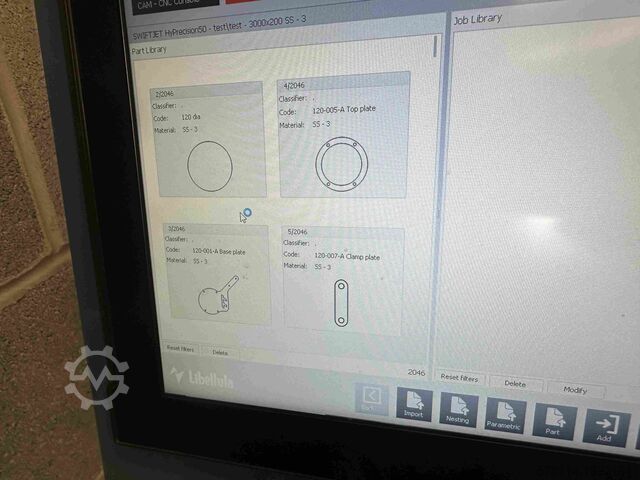

Ireland

Ireland Waterjet cutting machine

Swift-CutSwift-Jet SJ3000

Haßloch

Haßloch WJS NC 4030 B

Water Jet SwedenNC 4030B

What is meant by Water-jet cutting equipment and machines?

United Kingdom

United Kingdom Waterjet cutting machine

OMAX2652 Jet Machining Centre

Rennerod

Rennerod Water jet/plasma cutting system

Eckert Cutting TechnologyOpal WaterJet Combo

Czech Republic

Czech Republic Waterjet Cutting Machine

FlowMach M500-2060

Austria

Austria Waterjet cutting machines

Stein-Moser GmbHCNC 5 Achsen 4020 x 2020 x 600 mm

Poland

Poland Waterjet Cutting Machine

FlowMACH 3 3020B

Poland

Poland Waterjet Cutting Machine

MAVIJETMJT-W53D- 4020

Hungary

Hungary Waterjet Cutting Machine

Waterjet ItalyWL510

Serbia

Serbia Waterjet Cutting Machine

CMStecnocut JP 60hp

Used water-jet cutting equipment and machines (42)

Search Werktuigen now with more than 200,000 used machines:Browse through the most popular machine descriptions:

+49 201 857 86 180