Used electrical discharge machines (EDMs) for sale (379)

Used electrical discharge machines (EDMs) for sale (379)

Baden-Württemberg

Baden-Württemberg Die-sinking edm

CHARMILLESRoboform 2400

Wijchen

Wijchen Wire EDM machines Charmilles Robofil 190

CharmillesRobofil 190

Malakoff

Malakoff Wire eroding machine

MitsubishiEA12VM ADVANCE

+49 201 857 86 180

Lemmer

Lemmer Die-Sinking Spark Erosion 120 Amp.

Ona DaticPD-4.120 E0

Cloppenburg

Cloppenburg 2007 Vollmer QWD 760

VollmerQWD 760

Discover more used machines

Hungary

Hungary FANUC RoboCut alpha C600iA

FANUCRoboCut alpha C600iA

Bern

Bern Die-sinking edm

AGIE CHARMILLESROBOFORM 55

Dortmund

Dortmund Jig

KNUTH340 DS / 50 M

Monheim am Rhein

Monheim am Rhein Cavity Sinking EDM - Machine

ZIMMER & KREIMPEC 850

Wasbek

Wasbek Wire Cut EDM - Neospark T 500

KnuthNeospark T 500

Herscheid

Herscheid Wire eroding machine

MitsubishiMV 2400 S

Poland

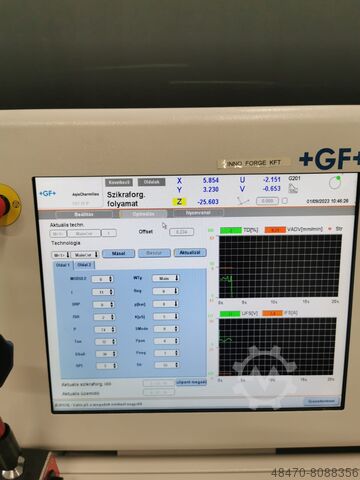

Poland +GF+ AgieCharmilles FO 350SP

+GF+AgieCharmilles FO 350SP

Iserlohn

Iserlohn Jig

AGIEEMT 1.20

Iserlohn

Iserlohn Jig

INGERSOLL HANSENGRANTRY 1000

Iserlohn

Iserlohn Start hole eroding machine

KOTONEDM-KTH-220 A

Spain

Spain ONA KE350

ONAKE350

Emmelshausen

Emmelshausen Wire erosion / EDM

AgieProgress V4

What is meant by Electrical discharge machines (EDMs)?

Electrical discharge machines (EDMs) are specialized tools used in manufacturing that remove material from a workpiece by using repeated electrical discharges—that is, sparks. These machines are particularly useful for machining hard metals or complex shapes that are difficult to handle with traditional mechanical cutting techniques. Two common types of EDMs include the wire EDM and the sinker EDM. Wire EDMs use a thin wire as an electrode to cut a programmed contour in a workpiece. Sinker EDMs, on the other hand, use a machined electrode that is shaped and then sunk into the base material to create the desired shape.

Electrical discharge machines (EDMs) are specialized tools used in manufacturing that remove material from a workpiece by using repeated electrical discharges—that is, sparks. These machines are particularly useful for machining hard metals or complex shapes that are difficult to handle with traditional mechanical cutting techniques. Two common types of EDMs include the wire EDM and the sinker EDM. Wire EDMs use a thin wire as an electrode to cut a programmed contour in a workpiece. Sinker EDMs, on the other hand, use a machined electrode that is shaped and then sunk into the base material to create the desired shape.

Iszkaszentgyörgy

Iszkaszentgyörgy Wire EDM

FANUCRobocut Alpha 0iB

Iszkaszentgyörgy

Iszkaszentgyörgy Wire cut EDM machine

ARISTECHCW30

Iszkaszentgyörgy

Iszkaszentgyörgy Wire EDM machine

FANUCRobocut Alpha 1C

Iszkaszentgyörgy

Iszkaszentgyörgy Cnc EDM Spark machine

NEUAR Precision Machinery Co. LtdCNC-C50E2

Iszkaszentgyörgy

Iszkaszentgyörgy Wirecut EDM

SodickALC600G

Székesfehérvár

Székesfehérvár Wire cut EDM

AGIE CHARMILLESCUT 20P

Rathenow

Rathenow CNC die-sinking EDM machine

EXERONS 306 MF20/30

Germany

Germany FANUC ROBOCUT α-0iA

FANUCROBOCUT α-0iA

Used electrical discharge machines (EDMs) (379)

Search Werktuigen now with more than 200,000 used machines:Browse through the most popular machine descriptions:

+49 201 857 86 180