Used CNC turning and milling centers for sale (664)

Sachsen-Anhalt

Sachsen-Anhalt CNC turn-mill center

DOOSAN DAEWOOPuma 300 MSC

Denkingen

Denkingen CNC turn-mill center

TsugamiHS20M-5AX

Germany

Germany CNC turn-mill center

MazakMULTIPLEX 6200-II Y

+49 201 857 86 180

Netherlands

Netherlands CNC turn-mill center

Doosan InfracorePuma 240C

Almere

Almere Cnc turning and milling center

OkumaLR15

Discover more used machines

Rot an der Rot

Rot an der Rot CNC turn-mill center

EMCOHyperturn 665 MC Plus

Sachsen-Anhalt

Sachsen-Anhalt CNC turn-mill center

SpinnerTC 52-MC

Blumberg

Blumberg CNC turn-mill center

CMZTX 66 2 Y

Haguenau

Haguenau CNC turn-mill center

mazak

Highgrounds Rd, High Grounds Rd, Worksop S80 3AT, UK

Highgrounds Rd, High Grounds Rd, Worksop S80 3AT, UK CNC turning and milling center

MazakE-410H Multi Tasking CNC Lathe

Nordrhein-Westfalen

Nordrhein-Westfalen CNC turn-mill center

MazakINTEGREX 400 Y

Kaufungen

Kaufungen CNC turning-milling machine

GildemeisterTwin 65 RG 2

Urgnano

Urgnano Cnc turning and milling center

BIGLIA SMART TURN 1200 L

Salzburg

Salzburg CNC turn-mill center

EMCOS65 TC

Berlin

Berlin CNC turning and milling center

Mori SeikiCL2000B

Highgrounds Rd, High Grounds Rd, Worksop S80 3AT, UK

Highgrounds Rd, High Grounds Rd, Worksop S80 3AT, UK CNC turning and milling center

MazakE-650H Multi Tasking CNC Lathe

Hornberg

Hornberg CNC turn-mill center

mügaA600

What is meant by CNC turning and milling centers?

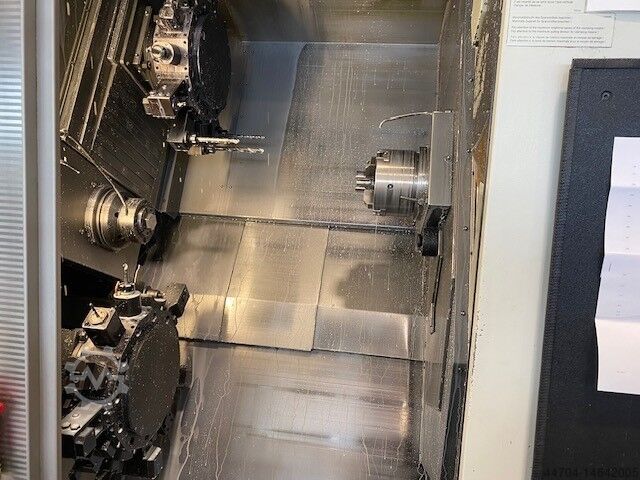

Combined CNC turning and milling centers, also known as multi-tasking or mill-turn centers, integrate the functionalities of both CNC lathes and CNC mills into a single machine. This hybrid design enables manufacturers to perform turning (rotating the workpiece) and milling (rotating the cutting tool) in one seamless process without needing to reposition or transfer the workpiece between machines.

Equipped with multiple spindles, tool turrets, and multi-axis capabilities (typically up to 5 axes or more), these centers allow for intricate part fabrication and precise machining from multiple angles and orientations. Complex parts requiring both cylindrical and non-cylindrical features—such as threads, grooves, slots, and holes—can be produced in a single setup.

The benefits include shorter production cycles, as the machine completes multiple operations in one setup, reducing workpiece handling time and potential misalignments. By consolidating processes, combined CNC turning and milling centers also contribute to higher consistency and quality control and reduce overall equipment costs, as a single machine can replace multiple standalone turning and milling units. These versatile centers are widely used in sectors such as aerospace, automotive, and medical device manufacturing, where precision, speed, and complex geometries are critical.

Combined CNC turning and milling centers, also known as multi-tasking or mill-turn centers, integrate the functionalities of both CNC lathes and CNC mills into a single machine. This hybrid design enables manufacturers to perform turning (rotating the workpiece) and milling (rotating the cutting tool) in one seamless process without needing to reposition or transfer the workpiece between machines.

Equipped with multiple spindles, tool turrets, and multi-axis capabilities (typically up to 5 axes or more), these centers allow for intricate part fabrication and precise machining from multiple angles and orientations. Complex parts requiring both cylindrical and non-cylindrical features—such as threads, grooves, slots, and holes—can be produced in a single setup.

The benefits include shorter production cycles, as the machine completes multiple operations in one setup, reducing workpiece handling time and potential misalignments. By consolidating processes, combined CNC turning and milling centers also contribute to higher consistency and quality control and reduce overall equipment costs, as a single machine can replace multiple standalone turning and milling units. These versatile centers are widely used in sectors such as aerospace, automotive, and medical device manufacturing, where precision, speed, and complex geometries are critical.

Kaniów

Kaniów Cnc turning and milling center

Gildemeister DMG CTX 310 V3

Freiburg im Breisgau

Freiburg im Breisgau CNC turn-mill center with Y-axis

Mori Seiki NL2500SY/700

Bruchsal

Bruchsal CNC turn-mill center

TraubTNS 65 D

Beringen

Beringen CNC Turning & milling center

MAZAKQTN 250M

Lorch

Lorch CNC turn-mill center

Mazak SQT 200 MSY

Nordrhein-Westfalen

Nordrhein-Westfalen CNC turn-mill center

GildemeisterCTX 410

Bayern

Bayern CNC turn-mill center

DMG MORINTX 2500/1500

Schweiz

Schweiz CNC Turning & milling machine

BENZINGERDOLittle B3/16

Used CNC turning and milling centers (664)

Search Werktuigen now with more than 200,000 used machines:

+49 201 857 86 180