Used Measuring machines for sale (556)

Wiefelstede

Wiefelstede Inside micrometer

Stahl35-145 mm

Wiefelstede

Wiefelstede Guideline

unbekannt3000/100/H15 mm

Wiefelstede

Wiefelstede Universal measuring system

imcµ-MUSYCS

+49 201 857 86 180

Wiefelstede

Wiefelstede Inside micrometer

Hommel Werke1500 mm

Wiefelstede

Wiefelstede Inside micrometer

Hommel Werke25-50 mm

Discover more used machines

Wiefelstede

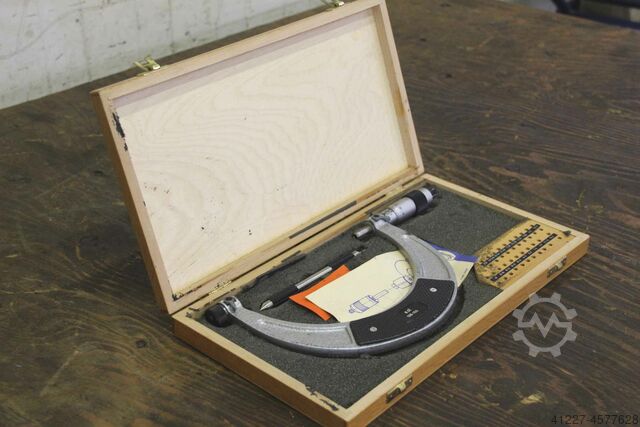

Wiefelstede Micrometer

Hommel-Werke300-400 mm

Wiefelstede

Wiefelstede Micrometer

Hommel400-500 mm

Wiefelstede

Wiefelstede Guideline

ANGULUS3000 mm

Wiefelstede

Wiefelstede Height indicator 600 mm

Mitutoyo600 mm

Wiefelstede

Wiefelstede Thread micrometer

Steinmeyer125 - 150 mm

Wiefelstede

Wiefelstede Thread micrometer

Steinmeyer75 - 100 mm

Wiefelstede

Wiefelstede Snap gauge 26 pieces

Friedehorst10-50 mm

Wiefelstede

Wiefelstede Measuring amplifier

HBMPME MP60

Wiefelstede

Wiefelstede Inside micrometer

Mauser800 mm

Wiefelstede

Wiefelstede 6 micrometers

Helios25 - 200 mm

Wiefelstede

Wiefelstede Height indicator 500 mm

Stahl500 mm

Wiefelstede

Wiefelstede Height indicator 300 mm

Stahl300 mm

How can I spot good Measuring machines?

Identifying a quality used measuring machine involves evaluating several key aspects. Firstly, consider the machine's accuracy and precision, typically documented in the manufacturer's specifications. Inspect the machine for physical damage and wear, especially on critical components like probes and scales. Secondly, verify its maintenance history to ensure it was regularly serviced and correctly calibrated. Lastly, testing the machine using standard measurements is advisable to check its operational reliability.

Accuracy and Precision Checks

Verify the accuracy by comparing the machine’s readings with known standards or calibration tools. Precision can be maintained only with meticulous periodic checks and calibrations, so evidence of these is a good sign.

Physical Condition and Component Integrity

Visually inspect the machine for any signs of misuse or excessive wear. Key components should be free of rust, corrosion, and any form of distortion. Smooth operation during testing can also indicate good mechanical health.

Maintenance and Calibration Records

A well-maintained machine will almost always have detailed maintenance logs. These records show the frequency and nature of any upgrades or calibrations, providing a sense of the machine's reliability and performance consistency over time.

Performance Testing

Conduct test measurements or ask for a demonstration using the device. This not only reassures you of its current functionality but also highlights any potential recalibration or repair needs.

Identifying a quality used measuring machine involves evaluating several key aspects. Firstly, consider the machine's accuracy and precision, typically documented in the manufacturer's specifications. Inspect the machine for physical damage and wear, especially on critical components like probes and scales. Secondly, verify its maintenance history to ensure it was regularly serviced and correctly calibrated. Lastly, testing the machine using standard measurements is advisable to check its operational reliability.

Accuracy and Precision Checks

Verify the accuracy by comparing the machine’s readings with known standards or calibration tools. Precision can be maintained only with meticulous periodic checks and calibrations, so evidence of these is a good sign.

Physical Condition and Component Integrity

Visually inspect the machine for any signs of misuse or excessive wear. Key components should be free of rust, corrosion, and any form of distortion. Smooth operation during testing can also indicate good mechanical health.

Maintenance and Calibration Records

A well-maintained machine will almost always have detailed maintenance logs. These records show the frequency and nature of any upgrades or calibrations, providing a sense of the machine's reliability and performance consistency over time.

Performance Testing

Conduct test measurements or ask for a demonstration using the device. This not only reassures you of its current functionality but also highlights any potential recalibration or repair needs.

Wiefelstede

Wiefelstede Dial gauge

IsserstedtDurchmesser 130 mm

Wiefelstede

Wiefelstede Position measuring system

FagorR NCT 13-005 3071 11A

Wiefelstede

Wiefelstede Micrometer

TESA200-225mm

Wiefelstede

Wiefelstede Height measuring device

Hommel Werke4626 DBP

Wiefelstede

Wiefelstede Measuring amplifier

LorenzGM40

Wiefelstede

Wiefelstede Micrometer

Hommel50-75 mm

Wiefelstede

Wiefelstede Dial gauge

Käfer0,01 mm

Wiefelstede

Wiefelstede Inside micrometer

Hommel Werke1500 mm

Used Measuring machines (556)

Search Werktuigen now with more than 200,000 used machines:

+49 201 857 86 180