Used gear measuring machines for sale (29)

Canada

Canada Gear Testing Machine

KLINGELNBERG-OERLIKONCS 200

Canada

Canada Gear Testing Machine

KLINGELNBERG-OERLIKONCS 200

Wiefelstede

Wiefelstede Measuring amplifier

KeyenceSJ-M300

+49 201 857 86 180

Germany

Germany Gear Testing Machine

HöFLERZP 350

Grüsch

Grüsch Gear Testing Machine

KLINGELNBERGPNC 30

Discover more used machines

Wiefelstede

Wiefelstede Measuring amplifier

KeyenceSJ-M300

Wiefelstede

Wiefelstede Internal micrometer

Mitutoyo511-901

Wiefelstede

Wiefelstede Measuring amplifier

HBMPME MP60

Wiefelstede

Wiefelstede Flow meter

FischerDE45N50041PK03MW

Wiefelstede

Wiefelstede Micrometers, 6 pieces

Helios25 - 200 mm

Wiefelstede

Wiefelstede Measuring amplifier

KeyenceSJ-M300 SJ-M030G

Wiefelstede

Wiefelstede Internal fine measuring device 35-60 mm

WMWINTOC 35-60 mm

Wiefelstede

Wiefelstede Pressure transmitter with display

NOVANova P 9302-1141-2011-200N1

Wiefelstede

Wiefelstede Universal measuring system

imcµ-MUSYCS

Wiefelstede

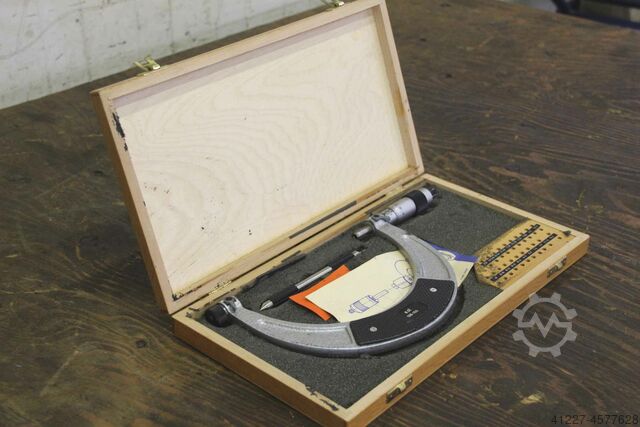

Wiefelstede Micrometer

Hommel400-500 mm

Wiefelstede

Wiefelstede Thread micrometer

Steinmeyer125 - 150 mm

Wiefelstede

Wiefelstede Thread micrometer

Steinmeyer75 - 100 mm

How can I spot good Gear measuring machines?

Identifying a high-quality gear measuring machine involves inspecting several key aspects. First, consider the model's precision and accuracy. High-resolution encoders and precise construction materials will ensure more accurate measurements. Additionally, check for modern software features that facilitate user-friendly interfaces, data management, and integration with other systems.

Condition and Maintenance History

Examine the physical condition of the machine and inquire about its maintenance history. A well-maintained machine, with regular calibrations and no significant damage or wear, typically offers better reliability and longer service life. Request documentation like service logs and calibration certificates to verify the machine's upkeep.

Brand and Manufacturer Support

The reputation of the manufacturer can also be a significant indicator of quality. Opt for brands known for their precision engineering and robust customer support. Availability of spare parts and technical assistance are essential for dealing with potential future issues.

Technology and Upgrades

Check if the gear measuring machine includes recent technological advancements. Features like automated measuring cycles, data connectivity, and compatibility with varying gear types can dramatically enhance efficiency and versatility in operations.

Identifying a high-quality gear measuring machine involves inspecting several key aspects. First, consider the model's precision and accuracy. High-resolution encoders and precise construction materials will ensure more accurate measurements. Additionally, check for modern software features that facilitate user-friendly interfaces, data management, and integration with other systems.

Condition and Maintenance History

Examine the physical condition of the machine and inquire about its maintenance history. A well-maintained machine, with regular calibrations and no significant damage or wear, typically offers better reliability and longer service life. Request documentation like service logs and calibration certificates to verify the machine's upkeep.

Brand and Manufacturer Support

The reputation of the manufacturer can also be a significant indicator of quality. Opt for brands known for their precision engineering and robust customer support. Availability of spare parts and technical assistance are essential for dealing with potential future issues.

Technology and Upgrades

Check if the gear measuring machine includes recent technological advancements. Features like automated measuring cycles, data connectivity, and compatibility with varying gear types can dramatically enhance efficiency and versatility in operations.

Wiefelstede

Wiefelstede Micrometer

TESA200-225mm

Wiefelstede

Wiefelstede Measuring amplifier

LorenzGM40

Wiefelstede

Wiefelstede Thread micrometer

Mauser75-100 mm

Wiefelstede

Wiefelstede Test pin set

Cary3,01 - 3,49 mm

Partenstein

Partenstein Gear testing machine

WenzelSmart Gear

Karlsruhe

Karlsruhe Gear measuring machine and rack measuring machine

WenzelWGT 350 XL

Wiefelstede

Wiefelstede Internal micrometer

Stahl35-145 mm

Wiefelstede

Wiefelstede Micrometer

Hommel225-250 mm

Used gear measuring machines (29)

Search Werktuigen now with more than 200,000 used machines:Browse through the most popular machine descriptions:

+49 201 857 86 180