Used Edgebanding machines for sale (997)

Germany

Germany Edge banding machine

HebrockAKV 069

Lohmar

Lohmar Edge banding machine

CEHISA1307

Bamberg

Bamberg Edge banding machine

Holzkraftminimax me 40 tr s

+49 201 857 86 180

Tauberbischofsheim

Tauberbischofsheim Edge banding machine Eumacop Eumafix-Top

EumacopEumafix-Top

Hilzingen

Hilzingen Brandt

BrandtKTD 68 CF

Discover more used machines

Cantù

Cantù Edgebander

VIRUTEX MEB 50

Germany

Germany Edge banding machine

FelderG 263-4

Rosmalen

Rosmalen Edgebander

ComevaCompacta E 4T (Pre-milling)

Klipphausen

Klipphausen Batch size 1 edgebander

SCMSTEFANI ONE

Bitburg

Bitburg Edge banding machine

IMACompact S 312

Roreto

Roreto Double-side SIZING&EDGE BANDING machine

STEFANI (SCM Group)Evolution C 220

Cantù

Cantù Edgebander

IDM - SCM GROUP IDIMATIC 49-20

Germany

Germany Edge banding machine

IMAQuadromat 3512 F

Rosmalen

Rosmalen Edgebander

VitapEclipse

Klipphausen

Klipphausen Edgebander with backfeed

SCMSTEFANI KD HP T-ERS + Barbaric RTS 04

Wörth an der Donau

Wörth an der Donau Edge banding machine

FORMAT4tempora F800 60.12-2

Cantù

Cantù Edgebander

SCMOLIMPIC K 500 T/ER-2

How can I spot good Edgebanding machines?

Good edgebanding machines are essential in woodworking and furniture manufacturing for applying edge materials like PVC, ABS, wood veneer, or melamine to panels. They ensure precise, durable, and visually appealing edges for cabinetry, furniture, and interior components.

Key Features of Good Edgebanding Machines

- Precision and Accuracy: High-quality machines deliver clean, seamless edges with precise trimming and gluing, ensuring a professional finish.

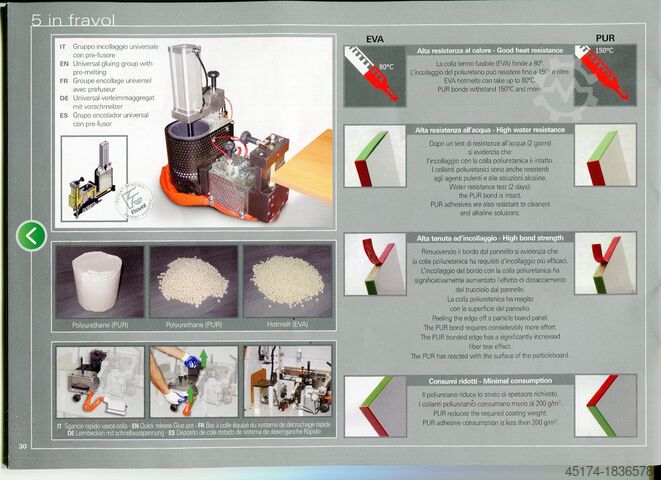

- Glue Application System: Efficient glue systems (e.g., EVA or PUR) allow for even distribution and strong adhesion, minimizing waste.

- Speed and Efficiency: Machines with adjustable feed speeds accommodate both small and large production volumes efficiently.

- Versatility: Good machines handle different edge materials (PVC, ABS, wood, etc.) and panel sizes with ease.

- Trimming and Finishing Units: Integrated trimming, scraping, and buffing units ensure smooth, polished edges with no residue or imperfections.

- User-Friendly Controls: Intuitive interfaces with digital displays and automated adjustments improve productivity and ease of use.

Good edgebanding machines are essential in woodworking and furniture manufacturing for applying edge materials like PVC, ABS, wood veneer, or melamine to panels. They ensure precise, durable, and visually appealing edges for cabinetry, furniture, and interior components.

Key Features of Good Edgebanding Machines

- Precision and Accuracy: High-quality machines deliver clean, seamless edges with precise trimming and gluing, ensuring a professional finish.

- Glue Application System: Efficient glue systems (e.g., EVA or PUR) allow for even distribution and strong adhesion, minimizing waste.

- Speed and Efficiency: Machines with adjustable feed speeds accommodate both small and large production volumes efficiently.

- Versatility: Good machines handle different edge materials (PVC, ABS, wood, etc.) and panel sizes with ease.

- Trimming and Finishing Units: Integrated trimming, scraping, and buffing units ensure smooth, polished edges with no residue or imperfections.

- User-Friendly Controls: Intuitive interfaces with digital displays and automated adjustments improve productivity and ease of use.

Germany

Germany Edge bander SCM Olimpic K 1000

SCMOlimpic K 1000

Klipphausen

Klipphausen Edgebander

SCMOLIMPIC K 560 R

Cantù

Cantù Edgebander

STEFANI ACTIVA 1-73

Germany

Germany Edge banding machine

HartmannHM 585

Cantù

Cantù Edgebander

FRAVOLRX 300

Cantù

Cantù Edgebander

CASADEI INDUSTRIA V 20/10 R

Cantù

Cantù Edgebander for pre-glued edges

FRAVOL - ITALY A 16 ACR -

Cantù

Cantù Edgebander

FRAVOL - ITALY RAPID RX 700

Used Edgebanding machines (997)

Search Werktuigen now with more than 200,000 used machines:

+49 201 857 86 180