Used spindle moulders / table mills for sale (146)

Wiefelstede

Wiefelstede Copy milling machine

elumatecAS 70

Wiefelstede

Wiefelstede Table milling machine

SCMT 110 A

Wiefelstede

Wiefelstede Table milling machine

MartinT 21

+49 201 857 86 180

Wiefelstede

Wiefelstede Copy router

elumatecAS 70/44

Wiefelstede

Wiefelstede Table milling machine

LubimezFR 101

Discover more used machines

Wiefelstede

Wiefelstede Table milling machine

AldingerES23

Wiefelstede

Wiefelstede Table milling machine

Stehle**mit Vorschub

Wiefelstede

Wiefelstede Table milling machine

MetaboTf 1690 D

Wiefelstede

Wiefelstede Table milling machine spare part

LubimezSpindel

Germany

Germany Milling machine

HofmannTischfräse

Gerolzhofen

Gerolzhofen Spindle moulder

HEMAGFraesrotor 190

Gerolzhofen

Gerolzhofen Spindle moulders

HOKUti 105

Gerolzhofen

Gerolzhofen Spindle moulders

HOLZKRAFT CASADEIF 25 LL-FK

Bitburg

Bitburg Table milling machine with rigid milling spindle

HolzkraftMinimax T 45 c LL

Juszczyn

Juszczyn Table mill

GriggioT2000

Lukovica

Lukovica Bench milling machine

SCMT150

Karsin

Karsin LUREM T50 spindle moulder

Luremt50

How can I spot good Spindle moulders / table mills?

To identify a high-quality spindle moulder or table mill, one of the key aspects to look at is the construction and durability of the machine. Check for any damages or signs of wear and ensure that all components are working smoothly without excessive noise or vibration. Assess the precision of the adjustments and the ease with which settings can be changed. A well-maintained tool should have clear, readable scales and should hold its settings throughout operation.

Check the Brand and Model

A reputable brand is often a good indicator of quality. Research the model to see if it has any known issues or recalls and look for user reviews or forum discussions to gauge how other professionals view its performance and reliability.

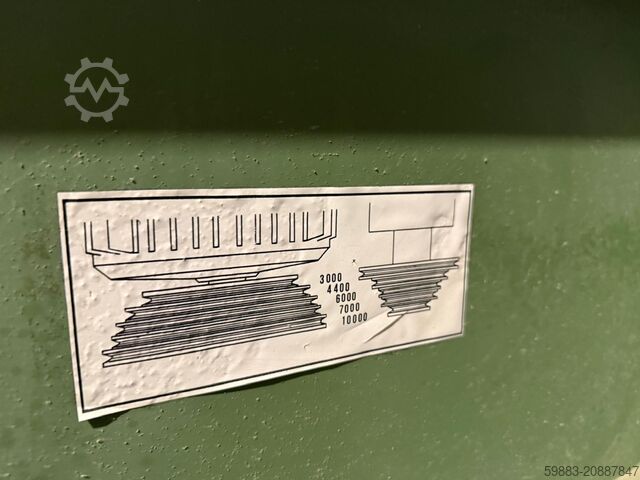

Inspect Power and Performance

The motor's power should be appropriate for the tasks you plan to undertake. Verify that the spindle moulder can handle the sizes and types of materials you intend to work with. Additionally, inspect the range and diversity of speeds available, as different materials and cut types require different spindle speeds.

Additional Features and Accessories

Consider what comes with the spindle moulder. Quality attachments and accessories can significantly enhance the machine's versatility. Look for things like adjustable fences, power feeders, and dust extraction systems which show that the machine can handle complex tasks and maintain a clean work environment.

Safety Features

Safety should never be overlooked. Ensure the machine includes essential safety features such as emergency stops, guards, and safety switches. These features are crucial to prevent accidents and ensure healthy working conditions.

To identify a high-quality spindle moulder or table mill, one of the key aspects to look at is the construction and durability of the machine. Check for any damages or signs of wear and ensure that all components are working smoothly without excessive noise or vibration. Assess the precision of the adjustments and the ease with which settings can be changed. A well-maintained tool should have clear, readable scales and should hold its settings throughout operation.

Check the Brand and Model

A reputable brand is often a good indicator of quality. Research the model to see if it has any known issues or recalls and look for user reviews or forum discussions to gauge how other professionals view its performance and reliability.

Inspect Power and Performance

The motor's power should be appropriate for the tasks you plan to undertake. Verify that the spindle moulder can handle the sizes and types of materials you intend to work with. Additionally, inspect the range and diversity of speeds available, as different materials and cut types require different spindle speeds.

Additional Features and Accessories

Consider what comes with the spindle moulder. Quality attachments and accessories can significantly enhance the machine's versatility. Look for things like adjustable fences, power feeders, and dust extraction systems which show that the machine can handle complex tasks and maintain a clean work environment.

Safety Features

Safety should never be overlooked. Ensure the machine includes essential safety features such as emergency stops, guards, and safety switches. These features are crucial to prevent accidents and ensure healthy working conditions.

Karsin

Karsin Spindle moulder KOLLE FS4

Köllefs4

Odry

Odry KINGISO MX5117H spindle moulder

kingisomx5517h

Kežmarok

Kežmarok Spindle moulder

Primultini35

Bad Honnef

Bad Honnef Table milling machine MARTIN T21 - used -

MARTINT21

Bad Honnef

Bad Honnef Table milling machine SCM T130 NPS - used -

SCMT130 NPS

Bad Honnef

Bad Honnef Table milling machine MARTIN -used-

MARTIN

Bad Honnef

Bad Honnef Bench router CASADEI F 25 LL FK Holzkraft CASADEI

CASADEIF 25 LL FK Holzkraft

Bad Honnef

Bad Honnef BÄUERLE SFM table milling machine -used-

VIETSFM

Used spindle moulders / table mills (146)

Search Werktuigen now with more than 200,000 used machines:Browse through the most popular machine descriptions:

+49 201 857 86 180