Used profile-grinding machines for sale (25)

Germany

Germany Profile Grinding Machine

ABAFUV 1250/60 CNC

Bitburg

Bitburg Comb. Pipe & Profile belt sander

MetallkraftKRBS 101

Leipzig

Leipzig Optical Profile Grinding Machine

WINTERMF-223

+49 201 857 86 180

Русе

Русе Splines grinding machine

МСЗ3451Б

Sochaczew

Sochaczew KAPP & CO RS 1203

KappRS 1203

Discover more used machines

Metzingen

Metzingen Optical Profile Grinding Machine

ABAPSM 2000

Mindelheim

Mindelheim Profile grinding machine

aba z&bStarline 2000 CNC

Marxzell

Marxzell Profile grinding machine

HOFFMANN74-41515070

Brügg

Brügg Tool and cutter grinder CNC

DOEBELI PETEWEFSM TFc

Aflenz Land

Aflenz Land Profile grinding machine

WasinoGLS-5T

Norken

Norken Optical profile grinding machine

Fritz WernerSP

's-Hertogenbosch

's-Hertogenbosch Profile grinding machine

z&bstarline 500 cnc

Sachsen-Anhalt

Sachsen-Anhalt Profile grinding machine

Ziersch & BaltruschProfilmaster 40/100 CNC

Schijndel

Schijndel CNC Optical Profile Grinding Machine

WasinoGLS-130AS

United Kingdom

United Kingdom Profile-grinding machine

JungVARIO-D

Fuldatal

Fuldatal Tube and Profile End Grinder belt

WIEGANDRPS-76

Norken

Norken Profile grinding machine

PETEWEPFS 30

How can I spot good Profile-grinding machines?

Identifying a high-quality profile-grinding machine involves examining several key aspects to ensure it meets your precision and durability requirements. Start by inspecting the machine's overall condition, focusing on signs of wear and tear on critical components such as the grinding wheel, spindle, and guideways. It's also crucial to check the accuracy and consistency of parts produced during a test run. Ask for maintenance records to gauge how well the machine has been kept.

Technical Specifications

Review the machine's technical specifications to ensure they align with your grinding needs. Key specifications include the maximum grinding length, grinding width, and the power of the motor. The machine's age can also be a crucial factor, as older machines might not have advanced features found in newer models but might offer robust construction.

Brand and Model Reputation

Research the brand and specific model of the profile-grinding machine. Established brands usually provide better reliability and after-sales service. Online reviews, user testimonials, and industry forums can offer insights into the machine’s performance and longevity.

Software and Controls

Modern profile-grinding machines come equipped with CNC controls that enhance precision and allow for complex grinding operations. Check if the software interface is user-friendly and capable of meeting your operation's complexity. Updates and support for the software should also be considered.

Accessories and Upgrades

Assess the availability of additional accessories and upgrades which can enhance the machine's capabilities. Availability of spare parts and the possibility of future upgrades can also contribute to the machine's operational longevity and versatility.

Service and Support

Finally, verify the availability and quality of technical support from the seller or manufacturer. This includes service response times, availability of technical assistance, and ease of access to replacement parts. A reliable support system can significantly reduce downtime and maintenance costs.

Identifying a high-quality profile-grinding machine involves examining several key aspects to ensure it meets your precision and durability requirements. Start by inspecting the machine's overall condition, focusing on signs of wear and tear on critical components such as the grinding wheel, spindle, and guideways. It's also crucial to check the accuracy and consistency of parts produced during a test run. Ask for maintenance records to gauge how well the machine has been kept.

Technical Specifications

Review the machine's technical specifications to ensure they align with your grinding needs. Key specifications include the maximum grinding length, grinding width, and the power of the motor. The machine's age can also be a crucial factor, as older machines might not have advanced features found in newer models but might offer robust construction.

Brand and Model Reputation

Research the brand and specific model of the profile-grinding machine. Established brands usually provide better reliability and after-sales service. Online reviews, user testimonials, and industry forums can offer insights into the machine’s performance and longevity.

Software and Controls

Modern profile-grinding machines come equipped with CNC controls that enhance precision and allow for complex grinding operations. Check if the software interface is user-friendly and capable of meeting your operation's complexity. Updates and support for the software should also be considered.

Accessories and Upgrades

Assess the availability of additional accessories and upgrades which can enhance the machine's capabilities. Availability of spare parts and the possibility of future upgrades can also contribute to the machine's operational longevity and versatility.

Service and Support

Finally, verify the availability and quality of technical support from the seller or manufacturer. This includes service response times, availability of technical assistance, and ease of access to replacement parts. A reliable support system can significantly reduce downtime and maintenance costs.

Liptovský Hrádok

Liptovský Hrádok Rondamat 960

WeinigRondamat 960

Contamine-sur-Arve

Contamine-sur-Arve Profile Grinder

WICKMANOPG

Großostheim

Großostheim Profile grinding machine

COSMOS

Nürnberg

Nürnberg Optical Profile Grinding Machine

BLOHMProfimat MC 610 S

Srbobran

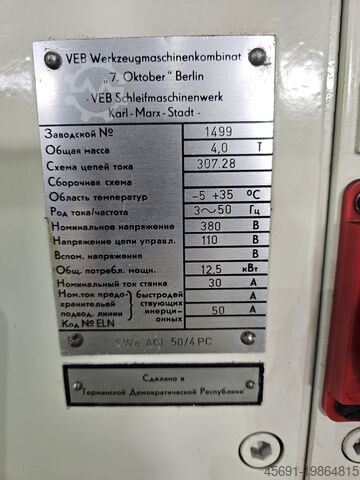

Srbobran Machines for grinding bearing rings

WMWSWa AGL-50, SWa AGL-125

Полтава

Полтава Profile-grinding machine

WasinoGLS-130AS

Nürnberg

Nürnberg Cylindrical Grinding Machine - Universal

BLOHMProfimat MC 610 S

Srbobran

Srbobran Machines for grinding bearing rings

WMWBWF - SIW 3E, SIW 4E

Used profile-grinding machines (25)

Search Werktuigen now with more than 200,000 used machines:Browse through the most popular machine descriptions:

+49 201 857 86 180