Used fruit & vegetable processing machines for sale (498)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Food processing machinery Fruit & vegetable processing machines

Listing

Domaszek

Domaszek

8,760 km

MPA 300 ELECTRIC PASTEURIZER

Maurer GépMPA 300

Call

Year of construction: 2026, condition: new, This machine is an electric pasteurizer which suitable for filling of bottles and bag-in-boxes.

- 100% stainless steel materials

- optionally with a bottle or a bag-in-box filling with digital scale

Specifications:

- Performance: 300 L/h (From 20°C to 80°C)

- Electric demands: 27 kW, 400 V, 32 A, triphase

- Material: WNr. 1.4301, AISI 304 stainless steel

- Dimensions: 600x1000x1850 mm

- Weight: 115 kg

- IP65 certified electronics

- Heat exchanger: soft water

- Connections: DN 25

- Level indicators for water and juice

- Thermometers: 2 pcs

Automatic heat control, very easy to clean. Manual, gravitational type.

With 4pcs wheels. It requires minimal maintenance.

Accessories: manual BiB filler with digital scale OR two head bottle filler module.

Available options:

- BiB AND bottle filler modules

- Stainless steel juice pump for refilling the upper tank

Itsdpfx Adofdz Dij Neb

Listing

Domaszek

Domaszek

8,760 km

MPA 180 ELECTRIC PASTEURIZER

Maurer GépMPA 180

Call

Year of construction: 2026, condition: new, This machine is an electric pasteurizer which suitable for filling of bottles and bag-in-boxes.

- 100% stainless steel materials

Itodpfxsfdz A Do Ad Neb

- optionally with a bottle or a bag-in-box filling with digital scale

Specifications:

- Performance: 180 L/h (From 20°C to 80°C)

- Electric demands: 18 kW, 400 V, 32 A, triphase

- Material: WNr. 1.4301, AISI 304 stainless steel

- Dimensions: 600x1000x1750 mm

- Weight: 85 kg

IP65 certified electronics

Heat exchanger: soft water

Connections: DN 25

Level indicators for water and juice

Thermometers: 2 pcs

Automatic heat control, very easy to clean. Manual, gravitational type.

With 4pcs wheels. It requires minimal maintenance.

Accessories: manual BiB filler with digital scale OR two head bottle filler module

Available options:

- BiB AND bottle filler modules

- Stainless steel juice pump for refilling the upper tank

Listing

Domaszék

Domaszék

8,761 km

MMD 3000 fruit washing machine

Maurer GépMMD 3000

Call

Year of construction: 2026, condition: new, machine/vehicle number: 123456, MMD 3000 Washing System with Pivoting Pulper

The unwashed fruit is loaded into the intake, where it undergoes pre-washing before being further cleaned by a fresh water spray on the conveyor belt. The system is easy to clean and is equipped with robust, food-grade polypropylene/acetal modular belts featuring infinitely variable conveyor speed in both directions. It comes with two swivel castors and two fixed rollers, or optionally with anti-vibration feet.

Requires minimal maintenance.

Technical Data:

- Rated capacity: 1,000–2,000 kg/h

- Power requirement: 3 kW, 400 V, 16 A, three-phase

- Material: Wnr. 1.4301, AISI 304 stainless steel

- Dimensions: 3325 x 800 x 2200 mm

- Discharge height: 1380 mm

- Weight: 240 kg

- Wash tank water capacity: 280 L/shift

- Water consumption: 20–100 L/h (depending on settings)

- Water connection: ¾” quick coupling

- IP65 electronics

- Continuously adjustable belt speed

- Pulper equipped with a robust hammer (also suitable for beetroot and quince)

Options:

- Different sieve inserts for the grating mill: for the desired fineness of fruit and vegetables

- Stop 'n' Go system – sensitive sensor enables the fruit washer and any type of belt press to operate in sync with the washing system without clogging

Itsdpfed Aqmzox Ad Nsb

- Adaptive electric valve – the fresh water jet operates only when the conveyor is running

- Air injection – with nozzles and a fan at the bottom of the tank for intensive washing

- Air knife – removes water from the fruit surface so that less water enters the end product

- Circulation pump with filter – ensures proper flow in the wash tank

Get information now

+49 201 857 86 180

+49 201 857 86 180

List now

*per listing / month

Listing

Domaszék

Domaszék

8,761 km

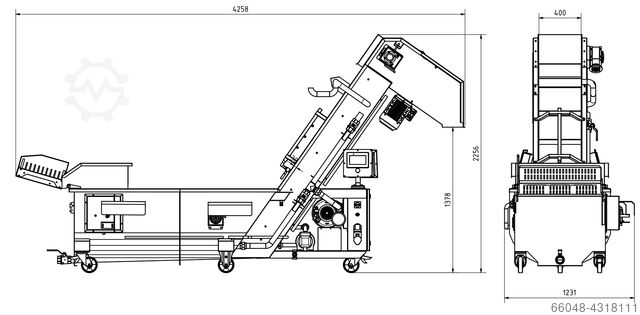

MLB 1000 BIN TIPPER

Maurer GépMLB 1000

Call

Year of construction: 2026, condition: new, The equipment MKLB 1000 is a device suitable for lifting and emptying crates used in agriculture. It may be stopped by the operator at any lifting or lowering position to ensure the economic transfer of materials. The equipment will hold such a position reliably. The material flow can be regulated by the angle of tilting.

Specifications:

- Performance: 20-25 tilt/h

- Max. bin weight: 1000 kg

- Electric demands: 0,75 kW, 400 V, 6 A, triphase

- Material: WNr. 1.4301, AISI 304 stainless steel

- Dimensions: 1800 x 1650 x 3000 mm

- Weight: 380 kg

- IP65 certified electronics

- Adjustable tilt speed

- Hydraulic system with “anti-fall” feature

- For different size bins

Itedpfxod Aqn To Ad Neb

- Steplessly adjustable tilt angle, with 4pcs vibration-free feet.

- It requires minimal maintenance.

- hydraulic lifting system

- variable box size capability

- can be stopped in any tilt position

Listing

Domaszék

Domaszék

8,761 km

Automatic packaging machine

IsarZS 6000

Call

Year of construction: 2025, operating hours: 1 h, condition: new, functionality: fully functional, MONTHLY OFFER – only in April!

The ZS 6000 automatic packaging machine is suitable for various vegetables such as potatoes, onions, carrots, cucumbers, beets, etc.

It is used for automatic, electronic weighing, filling Raschel mesh bags, and sewing or sealing the bags.

The harvested produce is metered from the bunker via a ribbed conveyor belt into the two electronic scales. The conveyor belt transports the harvested produce to the desired delivery point. Packaging units range from 1 to 25 kg.

Available in two versions: powder-coated or stainless steel

Technical specifications:

Capacity: approx. 6 t/h

Type / hour

5 kg – 1,690 kg

Iodpfx Adowax U Hs Njtb

10 kg – 2,600 kg

15 kg – 3,700 kg

20 kg – 6,120 kg

Power rating: 6 kW, 400 V

Packaging range: 1–25 kg (manual up to 50 kg)

Packaging type: Raschel net

Sewing machine: New Long NP-07 single-needle sewing machine

Control system: 7" touchscreen

Label dispenser

Conveyor belt with vibration motor

Dosing system with vibration system

Suitable for crops: Potatoes, onions, cucumbers, carrots

Dimensions:

Length: 1,940 mm

Width: 4,300 mm

Height: 2,230 mm

Weight: approx. 950 kg

Listing

Domaszék

Domaszék

8,758 km

MKT 100 Juice container

Maurer GépMKT 100

Call

Year of construction: 2026, condition: new, Specifications:

- Performance: 2000 L/h

- Electric demands: 0,5 kW, 230 V, 6 A, monophase

- Material: WNr. 1.4301, AISI 304 stainless steel

- Dimensions: 550x1075x350 mm

- Weight: 50 kg

- IP65 certified electronics

Iedpfx Adofhb I He Notb

- Food industrial impeller pump

- Juice level sensors

- Fully automatic operation, very easy to clean.

- With 4pcs wheels. Requires minimal maintenance.

- The machine is suitable for any Maurer press.

Listing

Domaszék

Domaszék

8,761 km

TANK BLOCK

Maurer Gép3X100L

Call

Year of construction: 2026, condition: new, machine/vehicle number: 1234, Műszaki adatok:

Kapacitás: 300 L

Anyagminőség: WNr. 1.4301, AISI 304 Rozsdamentes acél

Iodpfeiu Hy Ejx Ad Nstb

Méret: 1500x600x1100 mm

Súly: 60 kg

Csatlakozók száma: 2 db

Csatlakozók típusa: DN25 hollander

Szintjelzővel

Úszófedéllel

A blokk alkalmas a bérmunka során a különböző ügyfelek léhozamát külön tartályokba gyűjteni, majd a tartályok tartalma külön-külön pasztőrözhető/továbbítható megszakítás nélkül.

Nem igényel karbantartást.

Specifications:

Capacity: 300 L

Material: WNr. 1.4301, AISI 304 stainless steel

Dimensions: 1500x600x1100 mm

Weight: 60 kg

Number of connection: 2 db

Connections: DN 25

With level indicator

Floating top type

The block is available to handle other clients’ juices separately, and can be pasteurized separately without a brake. No need for maintenance.

Technische Daten:

- Kapazität: 3x100 Liter

- Material: WNr. 1.4301, AISI 304 Edelstahl

- Abmessungen: 1500x600x1100 mm

- Gewicht: 60 Kg

- Zahl der Anschlüsse: 1 St.

- Anschluss: DN 25

- Mit Füllstandsanzeige

- Mit Schwimmdeckel

- Es erfordert keine Wartung

Der Block ist geeignet, den Saft verschiedener Kunden während des Kontraktierens in getrennten Tanks zu sammeln, und der Inhalt der Tanks kann dann ohne Unterbrechung getrennt pasteurisiert/geliefert werden.

Listing

Domaszék

Domaszék

8,761 km

MSP 1400 BELT PRESS

Maurer GépMSP 1400

Call

Year of construction: 2026, condition: new, Specifications:

- Performance: 1400 kg/h

- Electric demands: 3 kW, 400 V, 6 A, triphase

- Material: WNr. 1.4301, AISI 304 stainless steel

- Dimensions: 2500x1330x1230 mm

- Input height: 1250 mm

- Output height: 370 mm

- Weight: 1150 kg

- IP65 certified electronics

Itodpfxod Aqzno Ad Nob

- Food industrial, massive polyester belt

- Belt: 2mm thick, density: 6x16 filament/cm^2, ½ rate (suitable for large fiber-free juice)

- High yield: 75% - depends on the freshness and quality of the fruits

- High-pressure washer demand: 500 L/h

- Compressed air demand: 50 L/h 6 bar

- Built-in inverter: steplessly adjustable belt speed

Fully automatic operation, with closed work area, reduces the oxidation to the minimum. In the bottom of the machine, there are two spinning washer heads guarantees optimal cleaning during the process. The distance between the press cylinder and the juice collector tray reduced against foaming. Very easy to clean.

With 4pcs vibration-free feet. It requires minimal maintenance.

High-pressure washer and air compressor are essential for operating.

Listing

Domaszék

Domaszék

8,761 km

HIGH PRESSURE HOMOGENIZER

Maurer Gép1000L

Call

Year of construction: 2026, condition: new, machine/vehicle number: 12134, Teljesítmény: 1000 L/óra, 7,5 kW

Maximum hőmérséklet: 90 °C

Feszültség: 400 V

Méret: 1300x1600x1500 mm

Súly:1000 kg

FBF 1000 High pressure homogeniser

Specification:

Capacity: 1000 L/h 7,5 kW

Maximum temperature: 90 °C

Two homogenizing phase: 1.: 200 bar, 2.: 50 bar

Feeding pressure requested: 2 bar

Voltage: 400 V

Consumption of water: 70-90 L/h

Consumption of air: 5 bar, 0,3 Nl/minute

Itedpfx Adsiu Hyzs Nsb

Gross size: 1300x1600x1500 mm

Gross weight:1000 kg

Compression head and valve:

- milled from one block

- high pressure resistant pistons

- vibration-free

Structure:

- vibration free pump

- power transmission through „V” belts, 1:2

- automatic oil lubrication with oil level indicator

Accessories:

- wearing part set

- tools

- oil

FBF 1000 Hochdruckhomogenisator

- Leistung: 1000 L / h 7,5 kW

- Maximale Betriebstemperatur: 90 ° C.

- Zweistufige Homogenisierung: 1 .: 200 bar, 2 .: 50 bar

- Versorgungsdruck mindestens 2 bar

- Stromspannung: 400V

- Wasserbedarf: 70-90 L / h

- Luftverbrauch: 5 bar, 0,3 Nl / min

Kompressionskopf und Ventil:

- Ein Block, der mit einer CNC-gesteuerten Maschine aus einem Block gefräst wurde, mit 5 Jahren Garantie.

- Kolben aus speziell gehärtetem Edelstahl.

- Energie- und kostengünstige Ventile sorgen aufgrund ihrer hohen Stabilität für einen vibrationsfreien Betrieb.

Struktur:

- Pumpe aus hochwertigem vibrationsfreiem Gusseisen

- Die Übertragung erfolgt auf "Keilriemen" mit Doppelübertragung

- 3-phasiger 4-poliger Motor

- Ölgeschmiertes Gehäuse mit Ölstandsfenster

Zubehör:

- Verschleißteilset

- Werkzeuge für die Wartung

- Schmieröl

- Anweisungen

Listing

Domaszek

Domaszek

8,760 km

MK MOBILE 900 FACTORY

Maurer GépMK MOBILE 900

Call

Year of construction: 2026, condition: new, Fruit processing where you want! The Mobile MK Fruit Processing Unit can be installed and operated anywhere. For operate, only water, electricity and gas or diesel are needed - then the processing can begin.

Ijdpfxod Atf So Ad Njtb

The processing machines can also be used separately by the Mobile MK fruit processing units independently. All machines are made of stainless steel. The vehicle body is made of aluminum and the box made of plastic. The unit is equipped with high-pressure cleaner, compressor and optional built on customer request with weatherproof pre-tent.

- Capacity: 800 kg / hour

- Weight: 3.5 tons (depends on the type and number of machines fitted)

- Equipped with compressor and high pressure washer

- Water, gas (or diesel), 10 KW of energy required for its operation

- Unique tent system against weather conditions

Listing

Domaszek

Domaszek

8,760 km

MK MOBILE FACTORY

Maurer GépMK MOBILE 600

Call

Year of construction: 2026, condition: new, Fruit processing where you want! The Mobile MK Fruit Processing Unit can be installed and operated anywhere. To operate, only water, electricity and gas or diesel are needed - then the processing can begin.

Itodod Arutspfx Ad Nob

The processing machines can also be used separately by the Mobile MK fruit processing units independently. All machines are made of stainless steel. The vehicle body is made of aluminum and the box made of plastic. The unit is equipped with high-pressure cleaner, compressor and optional built on customer request with weatherproof pre-tent.

- Capacity: 600 kg / hour

- Weight: 3 tons (depends on the type and number of machines fitted)

- Equipped with compressor and high-pressure washer

- Water, gas (or diesel), 10 KW of energy required for its operation

- Unique tent system against weather conditions

Listing

Domaszek

Domaszek

8,760 km

MLF 120 JAM COOKER

Maurer GépMLF 120

Call

Year of construction: 2026, condition: new, Inclusive mixer, with silicon scrapers against burning. Automatic heat control, very easy to clean. With 4pcs vibration-free feet. It requires minimal maintenance.

Specifications:

- Performance: 120 L/cycle

- Electric demands: 12 kW, 400 V, 32 A, triphase

- Material: WNr. 1.4301, AISI 304 stainless steel

- Dimensions: 850x800x1150 mm

- Weight: 200 kg

- IP65 certified electronics

- Heat exchanger: food industrial glycerin

- Thermometers: 1 pcs

- With security valve

Itjdpfx Adjfd Idcj Nsb

Listing

Domaszek

Domaszek

8,760 km

MDK 3000 brush washing system

Maurer GépMDK 3000

Call

Year of construction: 2026, condition: new, MDK 3000 Brush Washing Machine with Pulp Remover

The unwashed fruits are fed in at the intake. After pre-washing, they are cleaned again by an additional fresh water shower on the conveyor belt. The system is easy to clean and equipped with durable, food-grade polypropylene/acetal modular belts, featuring continuously adjustable belt speed in both directions. It comes with two swivel castors, two fixed castors, or alternatively anti-vibration feet. Minimal maintenance required.

Technical specifications:

- Rated capacity: 3,000 kg/h

- Power requirement: 5 kW, 400 V, 16 A, three-phase

- Material: Stainless steel Wnr. 1.4301, AISI 304

- Dimensions: 4300x1250x2222 mm

- Discharge height: 1,370 mm

- Weight: 420 kg

- Washing tank water capacity: 800 L/shift

- Water consumption: 100–200 L/h (depending on settings)

- Water connection: ¾” quick connector

- IP65 electronics

- Pulp remover equipped with a robust hammer (also suitable for beetroot and quince)

- Grating mill: may be electronically disengaged, enabling use of the washer for stone fruit

- Fitted with 4 counter-rotating brushes for intensive washing

- Rotating paddle pushes fruit towards the conveyor

Itedefd E R Uopfx Ad Neb

Options:

- Various sieve inserts for the grating mill for the desired fineness of fruit and vegetables

- Stop ‘n’ Go system – sensitive sensor allowing the fruit washer and all types of belt presses to operate clog-free in sync

- Adaptive electric valve – fresh water spray operates only when the conveyor is running

- Air injection – with nozzles and a fan at the bottom of the tank for intensive washing

- Air knife – removes water from fruit surface, so less water enters the final product

- Recirculation pump with filter – ensures correct flow in the washing tank

Listing

Domaszek

Domaszek

8,760 km

MPA 500 ELECTRIC PASTEURIZER

Maurer GépMPA 500

Call

Year of construction: 2026, condition: new, Specifications:

- Power: 500 L / h (when heated from 20 ° C to 80 ° C)

- Electricity requirement: 48 kW, 400 V

- Material quality: WNr. 1.4301, AISI 304 Stainless steel

- Size: 750x1950x1170mm

- Weight: 350 kg (without fuel)

- Heating medium: water (soft)

- IP65 certified electronics

- Connectors: DN25 Hollander

- with level indicator

Temperature control is done at 2 points in the heating medium and once at the outlet of the product. The machine automatically controls the heating medium temperature.

It is fully automatic. If the temperature of the juice to be pasteurized falls below the desired temperature, the output side of the machine is disabled and the juice circulates in the by-pass system until the temperature reaches the set level. The machine then starts charging again. At the end of the work, the tube spiral can be cleaned very easily with the help of a sponge ball. It requires minimal maintenance.

Ijdefdz Dkopfx Ad Netb

Listing

Domaszek

Domaszek

8,760 km

MASZ 25 DRYING CABINET

Maurer GépMASZ 25

Call

Year of construction: 2026, condition: new, Condensation drying of air and indirectly of foodstuffs (fruit, tea, mushrooms and such) is the most energy saving way of removing water from different materials. It works on the heat pump principle- by cooling on a steamer temperature below dew point is reached, due to which the surface of the steamer becomes wet with moisture from the air. The heat extracted from the air goes immediately back to the same air, with the help of electric energy needed for the operation of the compressor, 20-30% more heat is generated.

- suitable for drying various fruits (apple, plum, peach, etc.)

- adjustable temperature and humidity control

- automatic ventilation

- with stainless steel shelves

Specifications:

- Performance: 25-50 kg/cycle

- Electric demands: 0,6 kW, 230 V

- Drying temperature: 40-60°C

- Material: WNr. 1.4301, AISI 304 stainless steel

- Dimensions: 710x800x2000 mm

- Weight: 100 kg

- Number of trays: 11pcs

- Dimensions of trays: 570x570 mm

- Drying surface: ~3,6 m2

- IP65 certified electronics

- Continuous ventilation, consistent heat

- Insulation: 70 mm polyurethane

- Closed condensation circle, condensate drain

Itsdpfx Aed Atipsd Neb

Suitable for fruits, vegetables, herbs, spices, pastes, mushrooms.

Very easy to clean. Requires minimal maintenance.

Listing

Domaszek

Domaszek

8,760 km

MASZ 50 DOUBLE DRYING CABINET

Maurer GépMASZ 50

Call

Year of construction: 2026, condition: new, Condensation drying of air and indirectly of foodstuffs (fruit, tea, mushrooms and such) is the most energy-saving way of removing water from different materials. It works on the heat pump principle- by cooling on a steamer temperature below the dew point is reached, due to which the surface of the steamer becomes wet with moisture from the air. The heat extracted from the air goes immediately back to the same air, with the help of electric energy needed for the operation of the compressor, 20-30% more heat is generated.

- suitable for drying various fruits (apple, plum, peach, etc.)

- adjustable temperature and humidity control

- automatic ventilation

- with stainless steel shelves

Specifications:

- Performance: 50-100 kg/cycle

- Electric demands: 1,2 kW, 230 V

- Drying temperature: 40-60°C

Itedpfed Atghjx Ad Njb

- Material: WNr. 1.4301, AISI 304 stainless steel

- Dimensions: 1420x800x2000 mm

- Weight: 200 kg

- Number of trays: 22 pcs

- Dimensions of trays: 570x570 mm

- Drying surface: ~7,2 m2

- IP65 certified electronics

- Continuous ventilation, consistent heat

- Insulation: 70 mm polyurethane

- Closed condensation circle, condensate drain

Suitable for fruits, vegetables, herbs, spices, pastes, mushrooms.

Very easy to clean. It requires minimal maintenance.

Listing

Domaszek

Domaszek

8,760 km

MPAD 700 DIESEL PASTEURIZER

Maurer GépMPAD 700

Call

Year of construction: 2026, condition: new, Specifications:

- Performance: 700 L/h (From 20°C to 80°C)

- Electric demands: 1 kW, 230 V, 6 A, monophase

- Heat performance: 80kW (diesel burner)

- Fuel: diesel fuel

- Fuel consumption: 7,5 L/h

- Flue gas outlet: 110mm chimney

- Material: WNr. 1.4301, AISI 304 stainless steel

- Dimensions: 750x1700x1170 mm

Itedpfxefhb Ito Ad Neb

- Weight: 380 kg

- IP65 certified electronics

- Heat exchanger: soft water

- Connections: DN 25

- Thermometers: 2 pcs

- With automatic by-pass valve

- Automatic heat control, very easy to clean

- Automatic operation - flowthrough type

- With 4pcs vibration-free feet

- It requires minimal maintenance

Available options:

Two filler superstructure: BB top 180 semi-automatic BiB filler, 6 head bottle filler, puffer tank with level switches

Listing

Domaszek

Domaszek

8,760 km

MLB 300 BIN TIPPER

Maurer GépMLB 300

Call

Year of construction: 2026, condition: new, The equipment MLB 300 is a device suitable for lifting and emptying crates used in agriculture. It may be stopped by the operator at any lifting or lowering position to ensure the economic transfer of materials. The equipment will hold such position reliably. The material flow can be regulated by the angle of tilting.

- hydraulic lifting system

- variable box size capability

- can be stopped in any tilt position

Technical Data:

- Performance: 20-25 tilt/h

- Max. bin weight: 300 kg

- Electric demands: 0,55 kW, 400 V, 6 A, triphase

- Material: WNr. 1.4301, AISI 304 stainless steel

- Dimensions: 1290x1780x1260 mm

- Weight: 300 kg

- IP65 certified electronics

- Adjustable tilt speed

- Hydraulic system with “anti-fall” feature

- For standard size bins

- Steplessly adjustable tilt angle, with 4pcs vibration-free feet.

Itjdpfx Aoffyb Ejd Nob

- It requires minimal maintenance.

Listing

Domaszek

Domaszek

8,760 km

MPK 400 ELECTRIC BATH PASTEURIZER

Maurer GépMPK 400

Call

Year of construction: 2026, condition: new, Pasteurizing bath is suitable for the heat treatment of packaged fruit preparations (jam, wafers, herbs) or fermented preparations (vinegar, beer) and pickles. The packaging must be heat resistant as a glass or heat resistant plastic bag. The heat treatment technology is characterized by warming and holding, accurate temperature values and heat retention time by the product being treated and the user needs to know that the equipment only warms the treatment water and keeps it at the set temperature.

Ijdpfx Asfdzrnod Netb

Specifications:

- Performance: 400 L/cycle

- Electric demands: 18 kW, 400 V, 32 A, triphase

- Material: WNr. 1.4301, AISI 304 stainless steel

- Dimensions: 2500x1000x2000 mm

- Weight: 300 kg

- IP65 certified electronics

- Heat exchanger: soft water

- Thermometers: 1 pcs

Automatic heat control, very easy to clean. With 4pcs feet. Requires minimal maintenance. Built-in electric hoist for basket lifting-moving.

Listing

Domaszek

Domaszek

8,760 km

MM 3000 FRUIT WASHER

Maurer GépMM 3000

Call

Year of construction: 2026, condition: new, Specifications:

- Performance: 3000 kg/h

- Electric demands: 0,75 kW, 400 V, 16 A, triphase

- Material: WNr. 1.4301, AISI 304 stainless steel

- Dimensions: 750x2100x2800 mm

- Output height: 1820 mm

- Weight: 135 kg

- Tub water capacity: 280 L/shift

- Washing water supply: (20-100L/h depending on the setting)

- Water connection: 3/4“ quick connector

- IP65 certified electronics

The fruits go to the input hopper, after soaking the elevator towards the fruit under the secondary clearwater sprays.

Easy to clean, with massive polypropylene/acetal modular elevator, steplessly adjustable speed in both ways, with 2pcs rotating, 2pcs fix wheels.

Isdsfd E Tropfx Ad Netb

It requires minimal maintenance.

Listing

Domaszek

Domaszek

8,760 km

MLF 200 JAM COOKER

Maurer GépMLF 200

Call

Year of construction: 2026, condition: new, Inclusive mixer, with silicon scrapers against burning. Automatic heat control, very easy to clean. With 4pcs vibration-free feet. It requires minimal maintenance.

Specifications:

- Performance: 200 L/cycle

- Electric demands: 18 kW, 400 V, 32 A, triphase

- Material: WNr. 1.4301, AISI 304 stainless steel

- Dimensions: 900x800x1200 mm

- Weight: 350 kg

- IP65 certified electronics

- Heat exchanger: food industrial glycerin

Itodpsfd Idnsfx Ad Njb

- Thermometers: 1 pcs

- With security valve

Trust Seal

Dealers certified through Werktuigen

Listing

Domaszek

Domaszek

8,760 km

MVSZ 2000 SORTING/TRANSPORTING BELT

Maurer GépMVSZ 2000

Call

Year of construction: 2026, condition: new, The MVSZ 2000 sorting table is suitable for manually sort and deliver for the next workflow:

Technical data

- Performance: 3000 kg/h

- Electric demands: 0,55 kW, 230 V, 6 A, monophase

- Material: WNr. 1.4301, AISI 304 stainless steel

- Dimensions: 530x2530x1050 mm

- Output height: 1270 mm (+-100mm depends on the tilt angle)

- Weight: 110 kg

- IP65 certified electronics

- Tiltable work surface, adjustable height

- adjustable working speed

- Useful for our additional bin tippers and washers

Available options:

Itedsffycxjpfx Ad Neb

- Ribbed texture belt: it helps to prevent the fruits from rolling down in case of working on an angled surface.

Listing

Domaszék

Domaszék

8,761 km

MPK 100 ELECTRIC BATH PASTEURIZER

Maurer GépMPK 100

Call

Year of construction: 2026, condition: new, Pasteurizing bath is suitable for the heat treatment of packaged fruit preparations (jam, wafers, herbs) or fermented preparations (vinegar, beer) and pickles. The packaging must be heat resistant as a glass or heat resistant plastic bag. The heat treatment technology is characterized by warming and holding, accurate temperature values and heat retention time by the product being treated and the user needs to know that the equipment only warms the treatment water and keeps it at the set temperature.

Specifications:

- Performance: 100 L/cycle

- Electric demands: 9 kW, 400 V, 32 A, triphase

- Material: WNr. 1.4301, AISI 304 stainless steel

Iodpfxed Aq Ifj Ad Notb

- Dimensions: 500x1100x900 mm

- Weight: 75 kg

- IP65 certified electronics

- Heat exchanger: soft water

- Thermometers: 1 pcs

- Automatic heat control, very easy to clean.

- With 4pcs vibration-free feet. It requires minimal maintenance.

Listing

Domaszék

Domaszék

8,761 km

MLF 500 jam cooking kettle

Maurer GépMLF 500

Call

Year of construction: 2026, condition: new, MLF 500 Jam Cooking Kettle

Double-walled, insulated cooking kettle with food-grade glycerin as the heating medium. Equipped with an integrated stirring unit that prevents materials from sticking. The agitator motor is located at the bottom. The device automatically regulates the temperature of the heating medium. Fitted with heavy-duty feet. Fully automatic operation. Only minimal maintenance required.

Technical data:

Itsdpfx Asrz I Nwed Nob

- Rated capacity: 500 L per batch

- Power requirement: 37 kW, 400 V, 64 A, three-phase

- Material: Stainless steel Wnr. 1.4301, AISI 304

- Dimensions: 1700 x 1500 x 1600 mm

- Weight: 700 kg

- IP65 electronics

- Connection: DN100

- Equipped with safety valve

- Touch-screen control

- The machine's agitator is located at the bottom, which simplifies lifting the hinged lid. Silicone scrapers inside the kettle prevent burning of the jam.

- Minimal maintenance

Listing

Domaszék

Domaszék

8,761 km

MSP 1100 belt filter press

Maurer GépMSP 1100

Call

Year of construction: 2026, condition: new, MSP 1100 Belt Filter Press

The entire system can be disassembled down to the base frame within minutes!

Fully automatic fruit and vegetable press with a closed processing chamber to minimize oxidation. Two high-pressure nozzles are mounted beneath the machine and rotate continuously to ensure optimal performance. Due to the reduced distance between the press rollers and the juice collection tray, foam formation is no longer an issue. Most machine components can be disassembled without tools, making cleaning easy. Equipped with heavy-duty, vibration-damping machine feet. Requires minimal maintenance.

Technical Specifications:

- Rated capacity: 1,100 kg/h

- Power requirement: 1.5 kW, 400 V, 6 A, three-phase

- Material: Wnr. 1.4301, AISI 304 stainless steel

- Dimensions: 2200 x 1330 x 1200 mm

- Feed height: 1250 mm

- Dry matter discharge height: 470/770 mm

- Weight: 950 kg

- Includes integrated juice pump, collection tank, and level switch

- Touchscreen control

- Electronics to IP65

- Extra high juice yield: 75% (depending on freshness and quality of the produce)

- Air requirement: 50 l/hour at 6 bar

- High-pressure water requirement: 360 l/h

- Frequency inverter: variable speed control for even more professional processing

- High-strength, food-grade polyester press belt, fiber thickness: 2 mm, weave density: 6×16 fibers/cm², ½-twill weave (suitable for pressing without large fibers)

- Easy to clean

Itsdpfx Adjrz I Hqe Neb

- Requires minimal maintenance

- Adjustable, with vibration-damping machine feet

- Brush roller for belt cleaning

A high-pressure cleaner and air compressor are required for operation.

We make the search easier for you

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used fruit & vegetable processing machines (498)

Search Werktuigen now with more than 200,000 used machines:Browse through the most popular machine descriptions:

- Hurlimann H-6130

- Hurlimann H-6136

- International 1046

- International 1246

- International 1455

- International 3288

- International 353

- International 3688

- International 433

Get information now

+49 201 857 86 180

+49 201 857 86 180

List now

*per listing / month