Used flow forming machines for sale (20)

Babberich

Babberich Spinning machine LEIFELD Spinning moulds

LEIFELD

Nowa Pułapina

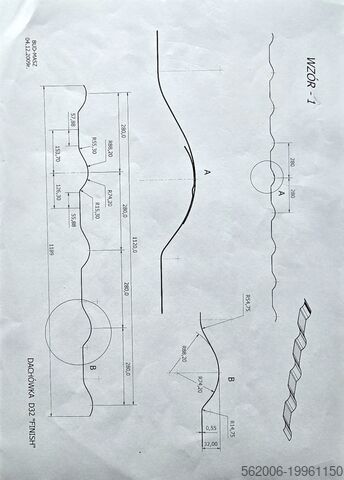

Nowa Pułapina Flow forming machine

BUD-MASZD32 Finish

Šibice

Šibice Eccentric press PRESSIX 40T

PRESSIX40CNV4

+49 201 857 86 180

Šibice

Šibice OMERA MODEL 63 R4

OMERAType 63 R4

Babberich

Babberich Spinning machine

LEIFELDPLB 1200

Discover more used machines

Boguchwała

Boguchwała Production line for chrome-nickel pipes

BOSSI

Debrecen

Debrecen Semi-automatic press machine

COMECPCV180

Babberich

Babberich Spinning machine LEIFELD - PLB 1200

LEIFELDPLB 1200

Ogre

Ogre Rollforming machine

FETHI YILMAZ MAKİNAROLLFORM MACHINE

Babberich

Babberich Trimming & bearding machine

OMERAR 1600

Most 1

Most 1 Straightening press

ZDASCDN 400 B

Ahlen

Ahlen Spinning machine

LeihfeldPS 35

Ahlen

Ahlen Support for pressing machine

LeihfeldPS 30

Ahlen

Ahlen Spinning machine

PenselDrückbank

Ahlen

Ahlen Spinning machine

Schulte DBDrückbank

Ahlen

Ahlen Spinning machine

LEIFELDPlb 300

Ahlen

Ahlen Spinning machine

LEIFELDPLB 300

What is meant by Flow forming machines?

Flow forming machines are advanced manufacturing equipment used primarily for the fabrication of metal tubes or cylindrical components. This technology involves the radial deformation of a metal blank, which rotates at high speeds. As the blank is spun, forming rollers apply pressure to elongate and compress the metal into the desired shape and thickness.

Key Features of Flow Forming Machines

- Precision: Allows for high-precision shaping and consistent thickness.

- Versatility: Can handle a variety of metals, including aluminum, steel, and titanium.

- Efficiency: Typically results in reduced waste compared to other forming processes.

- Customizability: Adjustable settings enable production of parts with various dimensions and properties.

Applications

Flow forming is used in industries where high-quality, durable cylindrical components are required. This includes automotive, aerospace, and military sectors, where parts like gears, wheels, and engine components need to meet strict specifications.

Flow forming machines are advanced manufacturing equipment used primarily for the fabrication of metal tubes or cylindrical components. This technology involves the radial deformation of a metal blank, which rotates at high speeds. As the blank is spun, forming rollers apply pressure to elongate and compress the metal into the desired shape and thickness.

Key Features of Flow Forming Machines

- Precision: Allows for high-precision shaping and consistent thickness.

- Versatility: Can handle a variety of metals, including aluminum, steel, and titanium.

- Efficiency: Typically results in reduced waste compared to other forming processes.

- Customizability: Adjustable settings enable production of parts with various dimensions and properties.

Applications

Flow forming is used in industries where high-quality, durable cylindrical components are required. This includes automotive, aerospace, and military sectors, where parts like gears, wheels, and engine components need to meet strict specifications.

Ahlen

Ahlen Spinning machine

LEIFELDPlb 300

Lippetal

Lippetal Spinning machine

LEIFELDPNC 350

Šibice

Šibice Transfer press Schroeder & Bauer HB 20

Schroeder + BauerHB 20

Used flow forming machines (20)

Search Werktuigen now with more than 200,000 used machines:Browse through the most popular machine descriptions:

+49 201 857 86 180