Used Barford Sxr 7000 for sale (1,258)

Sort results

- Lowest price Highest price

- Latest listings Oldest listings

- Shortest distance Farthest distance

- Latest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Latest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Latest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation A to Z

- Designation

- designation Z to A

- Designation

- Model A to Z

- Model

- Model Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest running time

- Runtime

- Relevance

- Relevance

Listing

Pfungstadt

Pfungstadt

7,851 km

Welding robot Cloos

CloosOmat 76 S / Rotrol 16/6 G

Call

Year of construction: 1991, operating hours: 18,100 h, Condition: excellent (used), machine/vehicle number: 1683268, Item number MA 1141

Manufacturer Cloos

type Romat 76 S / Rotrol 16 /6 G

Crob Eh Dnjh Rmrgjzjb

Year of manufacture 1991

Machine-No. 1683268

control Cloos Rotrol 16 /6 G with manual control panel ( the control panel is new)

weight [kg] 7000

Connected load 380V

Operating hours [h] 18100

Equipment The robot is still under power and in operation. It is equipped with a Mag welding source Cloos GLC 353 MC 3 R pulsed and a Tig welding source Cloos GLW 250 I-H.

Accessories manuals / 3 servo controllers were renewed

Listing

Rattelsdorf

Rattelsdorf

7,971 km

Planer and moulder

WEINIG 260 mmUnimat 1000 mit Nutenbett

Call

Condition: ready for operation (used), Year of construction: 2002, Functionality: fully functional, working width: 260 mm, planing height: 160 mm, spindle diameter: 50 mm, planing width: 260 mm, working height: 160 mm, power of feed motor: 4,000 W, spindle speed (max.): 6,000 rpm, spindle speed (min.): 6,000 rpm, height adjustment type: electric, type of input current: three-phase, number of spindles: 5, power: 39 kW (53.03 HP), frequency: 50 Hz, Equipment: cabin, motor brake, Weinig Unimat 1000 with grooved bed

Working width: 260 mm,

working height: 160 mm,

Go9Pfs

5 spindles

Spindle diameter- 50mm

Spindle arrangement:

1-bottom (7.5 kW) 7000 rpm

2-Right (7.5 kW) 7000 rpm

3-Left (7.5 kW) 7000 rpm

4-Top (7.5 kW) 7000 rpm

Csb Eh Dnsvft Imezsrb

5-bottom (5.5 kW) 7000 rpm

Feed rate: 4 kW / 6 - 36 m/min,

One driven roller in the table at the exit.

Listing

Schoonhoven

Schoonhoven

7,500 km

Bode Self Aligning Rotators (Steel Wheel

BODESAR 6000

Call

Condition: used, Year of construction: 2009, load capacity: 300,000 kg, Model No: SAR 6000

Capacity 300 Rotation & Load

Diameter Range 800mm min – 7000mm max

c/w Variable Speed Pendant Control

Warranty Period : 3 Months Parts Only

This is a rare opportunity to purchase three identical sets of the very latest 2009 Bode Self-Aligning Rotators. These machines have had minimum use and are offered in first-class condition. I am confident the first to see these will buy.

Crjb Eevrdagsh Dnzob

Each set has the added advantage of having anti-creep fitted to each idler unit.

Offered at a huge saving against new we invite customers to view these at anytime at our depot in Oud Castle Netherlands, located approximately 30 minutes from Rotterdam.

Find out now

+49 201 857 86 180

+49 201 857 86 180

Create listing

*per listing / month

Listing

Mannheim

Mannheim

7,866 km

Forklift battery Battery 80V 5PZS 700AH

Linde E25/30/35/40/45 - Linde K/P Jungheinrich EFG 430 - Toyota -Crown-uvm

Call

Condition: refurbished (used), Functionality: fully functional, Forklift battery with 1-year warranty

80V 5PZS 700AH

REMA 320 A plug installed - alternative plugs can be converted by arrangement

incl. Aquamatik for automatic filling of the cells with distilled water

Test date 2024

Dimensions: 1,028 x 855 x 784 mm

Weight: approx. 1,860 kg

Capacity: min. 90-100% (C5 protocol is enclosed with delivery)

Linde E25-325-00

Linde E25/600-336-00

Linde E25/600 HL-387-00

Linde E25/600 RHL-387-00

Linde E25/600 S -336-00

Linde E25 H-387-00

Linde E25 High-336-00

Linde E25 SH-1276-00

Linde E30-325-00

Linde E30 /600-336-00

Linde E30/600-RHL/HL-387-00

Linde E30 /600 S-336-00

Linde E30 H -387 -00/ High

Linde E30P - 325-00

Linde E30 SH -1276-00

Linde E35/600H - 388-00

Linde E35 H-/HL - 387-00

Linde E35 P - 337-00

Linde E35 RHL - 387-00

Cjb Ejuithpeh Dnzorb

Linde E35 SH-1276-00

Linde E40 - 337-00

Linde E40 C - 388-00

Linde E40 P - 337-00

Linde E45 / 600H - 388-00

Linde K 12/15-148-00

Linde P250 - 127-00

Linde P250L -127-05

Jungheinrich EFG 430

Toyota 7FBMF30/35

Toyota 8FBMT25

Crown TSP 6000-C

Crown TSP 7000

Caterpillar EP30K/FB35KPAC

Daewoo B30-35X

Daewoo B35X-7

Hyundai 50B-9

Mitsubishi FB25N

UniCarriers QX 2-30

and others.

All common battery sizes available, please enquire.

Listing

Saint Quentin-Fallavier

Saint Quentin-Fallavier

7,896 km

Box semitrailer

FruehaufSemitrailer Dryfreight Standard Porte relevante

Call

Condition: used, overall weight: 38,000 kg, empty load weight: 7,000 kg, maximum load weight: 31,000 kg, axle configuration: 3 axles, loading space length: 13,430 mm, loading space width: 2,310 mm, loading space height: 2,420 mm, loading space volume: 75 m³, first registration: 09/2017, next inspection (TÜV): 07/2025, suspension: air, color: white, tire size: 385/65 R22,5, Year of construction: 2017, mileage: 340,045 km, Equipment: ABS, Poids à vide: 7000kg, Poids total admissible: 38000kg, Espace de charge (L L H): 13.430 mm x 2.310 mm x 2.420 mmLa taille du pneu: 385/65 R22.5, Volume espace de charge: 75 m³, 1er essieu: , 2ème essieu: , 3ème essieu: , Suspension pneumatique, Dispositif anti- encastrement, Essieu relevable, Système de freinage électronique EBS, Porte-extincteur, Porte relevante, Compteur kms essieux, Fiche de raccordement 1x15 et 2x7 broches, Mines : 07/2025, Vous trouverez un aperçu de tous nos véhicules disponibles sur notre site web . Besoin d’un financement ? Nous proposons des financements individualisés, ainsi que du full-service ou un service télés serons heureux de vous conseiller personnellement.

Ceb Eh Djvvd E Dsnzsrb

Listing

Hessisch Lichtenau

Hessisch Lichtenau

7,826 km

Strip processing line, decoiler and straightener

HMS450 x 6

Call

Condition: used, Coil line, decoiler and straightener

Year of construction 1991

Strip width 50 to 450 mm

Sheet thickness with inactive straightener 6 mm

Sheet thickness with active straightener 2 mm

- Very good equipment and feeding aids

Space requirement of the entire system L x W approx. 7000 x 3000 mm

Weight of the entire system approx. 11 tons

good condition

Straightening machine HMS type RS 47-04/1, Machine. No. 00-0617/02

belt width, nominal width 400 mm

Strip width, maximum passage width max. 455 mm

Strip thickness at 400 mm width max. 1.5 mm (for steel)

Belt thickness at 400 mm width max. 2 mm (for copper)

Speed max. 40 m/min.

Number of straightening rollers 7 pieces

Straightening roller diameter Ø 40 mm

Number of tension rollers 2 pieces

Draw roller diameter Ø 80 mm

Infeed height, throughput height 1500 mm

- Straightening rollers hardened, ground and hard chrome-plated, with central support

- Draw rollers hardened, ground and hard chrome-plated, with hydraulic ventilation

- Manual straightening roller infeed

- Infeed aid with hydraulically extendable tongue and hydraulically adjustable deflection roller

- Adjustable lateral strip guide

- All straightening rollers driven via transfer gearbox with cardan shafts

- Both tension rollers driven via gearbox with cardan shafts

- Frequency-controlled drive via geared motors

- Straighteners Opening stroke 250 mm for cleaning the system or for running with thicker material, stroke movement via Trapetz threaded spindle

- Ultrasonic loop control

Transport dimensions L x W x H 3600 x 2200 x 2200 mm

Dead weight approx. 4 tons

Cob Eh Dnjif Sg Sszorb

Decoiler HMS type BA 1.5-06/80, Machine. No. 00-0617/01

Coil weight max. 8000 kg

Coil outside diameter max. 1600 mm (with loading chair)

Coil outer diameter max. 2000 mm (without loading chair)

Diameter of the coil starter disk Ø 1700 mm

Coil inner diameter, spreading range 460-520 mm

Coil width, nominal width max. 630 mm

Width of the spreading jaws 750 mm

Height of coiler crown above base plate 1500 mm

- Drive of the coiler crown via hydraulic motor and gear wheel

- Pneumatic overrunning brake on the TWINFLEX reel crown

- Hydraulic spreading of the reel crown, centrally via wedge slide system

- Hydraulic pressure arm with hydraulically driven double pendulum roller

- Coil loading chair with 12 ton. Lifting force and 300 mm stroke

- Reel in above-floor chassis with motorized transverse drive

Transport dimensions L x W x H 3500 x 1900 x 2500 mm

Dead weight approx. 5 tons

Central hydraulic unit opposite

Tank capacity 350 liters

Drive power 18.5 kW

- Drive motor with 2 REXROTH pumps (tandem pump)

- Oil cooler as air heat exchanger with fan motor

Transport dimensions L x W x H 1600 x 850 x 1450 mm

Tare weight approx. 800 kg

Electrical cabinet opposite

- All cable connections plugged in via Harting plugs

Transport dimensions L x W x H 2800 x 500 x 2250 mm

Dead weight approx. 800 kg

Listing

Kaufungen

Kaufungen

7,815 km

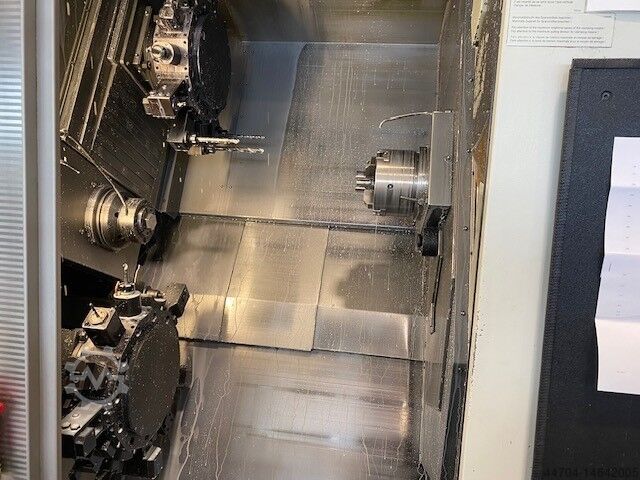

CNC turning-milling machine

GildemeisterTwin 65 RG 2

Call

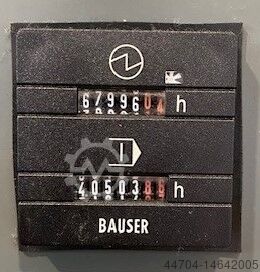

Condition: good (used), Year of construction: 2008, 1 used CNC turning/milling center

Gildemeister

type TWIN 65 RG 2 year 2008

with Siemens 840 D

Maximum turning length (travel in the Z axis) 650 mm

Maximum turning diameter over bed 250 mm

Maximum length of travel in the X-axis 300 mm

Maximum feed speed X-axis 30 m/min

Maximum feed speed Z axis 30 m/min

Maximum main spindle power 35 kW

Spindle diameter 65 mm

Minimum main spindle speed 20 1/min

Maximum main spindle speed 5000 1/min

Lathe length 7000 mm

Lathe width 4700 mm

Lathe height 2500 mm

Lathe weight 10 t

Machine equipment

Y axis

Irco loading magazine ILS RBK 1200 mm

Workpiece pick-up device

Technical data Errors excepted

Please note that the machine is sold without chucks, as these remain with the seller!

Cob Eh Dsq T I Izsnzerb

Listing

Lievegem

Lievegem

7,473 km

Dump truck

MANTGA 430 PK

Call

Condition: used, mileage: 427,000 km, fuel type: diesel, emission class: euro3, Year of construction: 2006, Brand M.A.N.

Type: TGA 430 hp

Year of construction 2006

427000 KM

Manual gearbox

Tipper

Crsb Eh Djvpd Tusnzjb

id nr 51

Auction

Auction ended

England

England

7,109 km

Double turret lathe

OkumaTwin Star LT200-M

Condition: good (used), Year of construction: 2004, Functionality: fully functional, machine/vehicle number: 112793, TECHNICAL DETAILS

Machining diameter: max. 240 mm

turning length: max. 700 mm

Speed: 6000 rpm

Bar capacity: 55 mm

Control unit: OSP-E100L

Turret: 2 x 12 stations

Number of driven stations: 2 x 10

Tool speed: 5000 rpm

Tool holder: VDI 30

Collet chuck: 2 x Power Chuck,

Crjb Eh Djtuva Tonzeb

MACHINE DETAILS

Machine dimensions: 2700 x 2000 x 1980 mm

Weight: 7000 kg

EQUIPMENT

- Tailstock

- Tool equipment

- Chip conveyor

- tools

- Bar loader IEMCA Vip 80-E

- coolant

Listing

Mannheim

Mannheim

7,866 km

Forklift battery Battery 80V 4PZS 620AH

Linde E20 E25 E30 E35 E40 - K,-P Jungheinrich EFG 25-/425-/430 Toyota uvm

Call

Condition: refurbished (used), Functionality: fully functional, Forklift battery with 1-year warranty

80V 4PZS 620AH

REMA 320 A plug installed - alternative plugs can be converted by arrangement

incl. Aquamatik for automatic filling of the cells with distilled water

Test date 2024

Dimensions: 1025 x 708 x 784 mm

Weight: approx. 1,558 kg

Capacity: min. 90-100%

Suitable for the following models and others:

Linde E 20 - 325-00

Linde E 20 / 600 - 387-00

Linde E 20 / 600 H - 1252-01

Linde E 20 / 600 H - 387-00

Linde E 20 / 600 RH - 387-00

Linde E 20 H - 387-00

Linde E 20 HOCH - 325-00

Linde E 20 HOCH - 336-00

Linde E 20 P - 325-00

Linde E 20 Z - 325-00

Linde E 25 - 325-00

Linde E 25 - 336-00

Linde E 25 - 387-00

Linde E 25 / 600 - 387-00

Linde E 25 / 600 H - 1252-01

Linde E 25 / 600 H - 387-00

Linde E 25 / 600 RH - 387-00

Linde E 25 CH - 387-00

Linde E 25 H - 387-00

Linde E 30 CH - 387-00

Linde E 30 H - 387-00

Linde E 30 P - 325-00

Linde E 30 SH - 1276-00

Linde E 35 - 337-00

Linde E 35 - 337-02

Linde E 35 P - 337-00

Linde E 40 P - 337-00

Linde K - 5231-00

Linde K - 5231-00 - lateral change

Linde K 12 - 02 - 148-00

Linde K 15 - 148-00

Linde P 200 - 370-00

Linde P 250 - 127-00 - vertical changeover

Linde P 250 S - 127-05

Linde P 250 SWB - 5007-10 - lateral change

Linde P 250 SWB - 5007-10 - vertical changeover

Still MX-X

Still R. 07-25

Still R 60-20

Still R 60-22

Still R 60-25

Still RX 60-25

Still RX 60-30

Jungheinrich EFG 25

Jungheinrich EFG 425

Jungheinrich EFG 430

Jungheinrich EFG 430 K

Jungheinrich EFG 425 K

Jungheinrich EFG V 25

Jungheinrich EKX 515

Jungheinrich EKX 515 K

Jungheinrich EKX 525 K

Jungheinrich ETX

Toyota 7FBMF20

Toyota 7FBMF25

Cober Ak Hgs Eh Dnzorb

Toyota 8FBMKT25

Toyota 8FBMKTB0

Toyota FBM25

Toyota FBMF20

Toyota FBMF25

Crown TSP 6000 - B

Crown TSP 6000 - C

Crown TSP 7000

Atlet EH 25

Balkancar EV715

Balkancar EV720

Clark GEX25

Heli CPD 30

Heli CPD 35

Hubtex MQ 40

Hyster E5XN

Hyster J2.0

Hyundai 25BHA7

Mitsubishi FB25CN

Nissan 1Q2L25Q

Nissan QX25

All common battery sizes available, please enquire.

Listing

Zuchwil

Zuchwil

7,953 km

Automatic lathe

STARSV-32

Call

Condition: good (used), STAR SV-32 CNC sliding headstock automatic lathe

TECHNICAL DATA

Main spindle, bar capacity: 32 mm

Travel: 310 mm

Spindle speed: 7000 rpm

Spindle drive power: 7.5 kW

Minimum resolution, C-axis: 0.01 °

Counter spindle, bar capacity: 32 mm

Spindle speed: 7000 rpm

Spindle drive power: 7.5 kW

Resolution, C-axis: 0.01 °

Turret:

Number of tools: 10

of which driven: 10

Speed of the driven tools: 5`700 rpm

Driven tools, power: 2.8 kW

Tool carrier:

Number of tools: 4

Of which driven: 3

Speed of the driven tools: 6'000 rpm

Weight and dimensions:

Weight: 3800 kg

Dimensions: 2700 x 1400 x 2400 mm

Crjb Eh Dsu Uicyonzjb

SCOPE OF OFFER

U.A: (list not exhaustive)

Control system: Fanuc

Fire extinguishing system: Siemens

Oil mist separator: Donaldson

transformer

High pressure pump

Parts conveyor

Chip conveyor

Exact scope of supply according to photo gallery

We assume no liability for the correctness, completeness and up-to-dateness of the information.

Listing

Hessisch Lichtenau

Hessisch Lichtenau

7,826 km

Hydraulic pellet press or briquette press; for grinding sludge, metal chips or similar

RUFRBK 55/2500/120 S

Call

Condition: used, Revolving briquetting press RUF type RBK 55/2500/120 S

Hydraulic pellet press or briquetting press

for grinding sludge, metal chips, or similar

No. 70002 Year of construction 2009

Briquette diameter 120 mm

Briquette length in the pre-compactor approx. 120 mm

Pressing force in the pre-compactor 30 tons at 260 bar

Briquette length in the main compactor approx. 80 mm

Pressing force of the main press cylinder 250 tons at 260 bar

Stroke size of the main press cylinder 120 mm

Pressing force of the counter-press cylinder 250 tons at 260 bar

Stroke size of the counterpress cylinder 15 mm

Piston diameter of the main press cylinder 350 mm

Press stroke Cycle time approx. 30 sec. for grinding sludge with low residual oil content

Hopper size of the screw conveyor 1000 x 600 mm

Hydraulic motor power 37 kW

Mains connection 400 Volt, 50 Hz, 45 kW

- Revolver with 5 stations for high material throughput

- Pre-compressor stage for pressing material into the turret disk

Crjbshg Uz Io Eh Dnzob

- 2 opposing main press cylinders with 120 mm and 15 mm stroke

- Ejection cylinder for ejecting the finished briquettes from the turret disk

- Infinitely variable adjustment of the hydraulic speed for each pressing stage

- was used for grinding sludge from metal processing

- Material hopper as hopper with screw conveyor

- the machine was completely overhauled at RUF in 2018

- a new SIEMENS Simatic touch panel was installed in 2020

- only a few operating hours after the overhaul

very good condition

Grinding sludge recycling

- great savings through cooling lubricant recovery

- Large savings in disposal costs due to the reduction in volume and weight of the grinding sludge

- Grinding sludge briquettes with a low residual oil content can possibly be classified as "non-hazardous waste".

Listing

Fumane (Verona)

Fumane (Verona)

8,269 km

Rinsing Machine

Vir Mauri

Call

Condition: used, Year of construction: 1990, Used Overhauled Rinsing Machine

The Used Overhauled Rinsing Machine Virmauri rinsing machine, built in 1990 and overhauled, is an industrial machine dedicated to the treatment of glass containers. With an operating capacity of 7000 bottles per hour (BPH), the device implements a system of 28 grippers for the optimization of rinsing processes. Operating clockwise, this unit features movable nozzles, allowing flexibility in specific treatment for each container.

Cob Eh Dsvgvwasnzjrb

Mechanics and Operation

Focusing on mechanics, the device adopts a single-step treatment approach, using water as the main cleaning agent. This choice, while simplifying the process, imposes stringent requirements on the quality of the water used and on the maintenance of the nozzles to prevent cross-contamination.

The clockwise rotation direction and the arrangement of the sockets have been designed to optimize the workflow and minimize downtime during production batch changes. These technical aspects require careful evaluation when integrating the machine into existing production lines.

Current Status and Maintenance of Used Overhauled Rinsing Machine

Regarding the current status of Virmauri, the used overhouled rinsing machine is classified “On stock”, indicating immediate availability for installation and use post-overhaul. The Used Overhauled Rinsing Machine has undergone an overhaul process to ensure its functionality and reliability over time. Maintenance management requires a meticulous approach to ensure the availability of spare parts and the technical competence for rapid interventions.

Conclusions of Virmauri rinser equipment:

In conclusion, the 1990 Virmauri rinser, with 28 grippers and a capacity of 7000 BPH, represents a technologically viable option for companies in the bottling industry that need an efficient and reliable unit for processing glass containers. The decision to acquire a machine of this nature requires a detailed analysis of your production needs, compatibility with existing lines and internal maintenance capabilities, to ensure optimal integration and operation.

We can assure full service on this Virmauri equipment with our staff.

Listing

Strassberg

Strassberg

7,985 km

Pneumatic Hammer

Huta ZygmuntMPM 6300

Call

Condition: used, Year of construction: 1978, Blow energy: 7000 kg/m

Max. stroke: 850 mm

Crjbsvam D Rs Eh Dnzjb

Max. stroke rate: 100 s.p.m.

Length of die seat in ram: 650 mm

Ram weight: 2500 kg

Die seat length in die holder: 900 mm

Min. die thickness: 300 mm

Max. upper die weight: 800 kg

Operating height: 780 mm

Anvil weight: 47500 kg

Weight of machine approx.: 64000 kg

Listing

Hessisch Lichtenau

Hessisch Lichtenau

7,826 km

Hydraulic plate shears

STEINERHTS 30 / 20 R

Call

Condition: used, Hydraulic guillotine shear STEINER type HTS 30/20 R

Machine. No. 315 Year of construction 1982

cutting length 3050 mm

Cjbjd Hxx Ae Eh Dnzsrb

cutting thickness 20 mm

backgauge 800 mm controlled

motor power approx. 30 kW

mains connection 400 Volt, 50 Hz

- backgauge with positioning control ELGO

- backgauge adjustment via ball screws

- Safety light barrier SICK at the front as intervention protection

- 3 material support arms with ball rollers

- electric foot switch

- spare blade

Space requirement of the basic machine L x W x H 4650 x 2610 x 3200 mm

Weight of the basic machine 27000 kg

Space requirement for transport (basic machine) L x W x H 4650 x 2610 x 3200 mm

Space requirement for transport (additional) L x W x H 3500 x 2450 x 1400 mm

Weight complete 27000 kg

Mechanically in very good condition

Hydraulic problems, Electrical control in need of overhaul.

Listing

Fumane (Verona)

Fumane (Verona)

8,269 km

Capping Machine

Bertolaso5T

Call

Condition: used, Year of construction: 2000, Used Capping Machine BERTOLASO plastic T stopper up to 7000 bph

This capping machine not only delivers high performance in the bottling sector but also ensures efficiency. The Bertolaso 5T model processes about 7000 bottles per hour (BPH), which makes it ideal for medium to high-capacity bottling lines. It features 5 capping heads, allowing it to apply plastic mushroom stoppers, also known as T stoppers, that are commonly used in wine and other alcoholic beverages.

Technical Features of the Capper BERTOLASO 5T

Bertolaso designed the 5T model with a robust structure that therefore ensures long-term durability and resistance to wear and external elements. The machine’s mobile capping heads provide flexibility during the capping process, so it adapts to different cap formats. Bottles enter from the left side, and the machine rotates clockwise, in accordance with industry standards. Moreover, the vibrating cap feeder ensures a continuous and smooth supply of caps to the production line.

Safety and Compliance

The capper Bertolaso includes safety guards that comply with current occupational safety regulations. These guards thus ensure maximum safety for operators, reducing the risk of accidents. In addition, the design of the guards allows easy access to the machine without interfering with its regular operation, making maintenance tasks more efficient.

Performance and Flexibility

The Used Capping Machine BERTOLASO plastic T stopper up to 7000 bph handles up to two formats of cylindrical bottles. Consequently, this flexibility allows production lines to adapt to various requirements without long downtimes for reconfiguration. Operators can adjust production speed through a variable speed drive, thereby aligning the machine’s output with specific production needs. As a result, the machine provides tailored performance based on your specific requirements.

Crjb Eh Dnovgviiozeb

Current Status and Sales Conditions

The machine is currently stored and ready for inspection and reinstallation. Furthermore, we will supply the machine with an existing cylindrical bottle format and cap installed on the capping machine. This means that the setup simplifies installation and startup, enabling quick integration into your production line. The machine operates on a 380 V and 50 Hz electrical system, which makes it fully compatible with European industrial standards. Hence, you can integrate it seamlessly into your production setup.

Conclusion of the Capper BERTOLASO 5T

Overall, the Used Capping Machine BERTOLASO plastic T stopper up to 7000 bph offers an efficient, versatile solution for bottling lines requiring reliable, high-speed production. Additionally, its technical features, format flexibility, and safety guards make it an excellent choice for those seeking a high-quality capping machine. Thus, by choosing this model, you ensure both performance and safety. In short, it is a top-tier machine that will enhance your production line’s efficiency.

Listing

Hessisch Lichtenau

Hessisch Lichtenau

7,826 km

2-axis linear guide with linear motors - Slide arm pick and place with linear guides for automation

SCHUNK - GEMOTEC - AFAG - LINMOTPS01-37x240-M + E1100-MT + T01-/72/420 + EPM 37-78

Call

Condition: used, 2-axis linear guide with linear motors - Slide arm pick and place with linear guides for automation

Loading unit such as Scara robot, manipulator, handling device, handling system, placement gripper, loading gripper for automation

Manufacturer SCHUNK - GEMOTEC - AFAG - LINMOT Type PS01-37x240-M + E1100-MT + T01-/72/420 + EPM 37-780

Year of construction approx. 2005

Horizontal axis with linear motor Gemotec type EPM 37-780

Actuator type: EPM 37x780-M

Axis module: LinMot type E1100-MT-HC

Horizontal movement: 780 mm

Nominal force horizontal: 160 N

Horizontal speed: 2.1 m/s

Horizontal acceleration: 12.4 m/s²

Repeat accuracy: +/- 0.05 mm

Horizontal load capacity: max. 7000 g

Horizontal guide column: Ø 20 mm

Vertical axis with LinMot linear motor type PS01-37x240-M

Actuator type: LM01-23x80/160

Axis module: LinMot type E1100-MT

Vertical movement 160 mm

Nominal vertical force: 44 N

Max force vertical: 203 N

Vertical speed: 2.2 m/s

Vertical acceleration: 50.4 m/s²

Repeat accuracy: +/- 0.05 mm

Crsbeu H R Iws Eh Dnzob

Horizontal guide column: Ø 20 mm

Power supply unit LinMot type T01-/72/420 (for motor supply)

Input voltage: 3 x 400 V AC 50/60 Hz

Output voltage: 72 V DC 420 Watt

Base frame Support columns: 4 pieces Ø 55 mm

Support column height adjustment: 200 mm (manual height adjustment)

Mounting foot: 2 x 175 x 90 mm

Control voltage: 24 V DC

- Can be moved in two axes

- Mounting plate for tool holder 66 x 56 mm

- Integrated path measurement

- Axis modules with integrated positioning control

- Festo pneumatic cylinder as holding brake on the vertical axis

- Horizontal axis with 3 external fans

- Axis modules configurable via LinMot MPC Configurator 3.2 software

Space requirement L x W x H: 1120 x 720 x 740 mm

Weight: approx. 65 kg

Very good condition

Listing

Fumane (Verona)

Fumane (Verona)

8,269 km

Filling Monoblock

MBF50.70.12.10

Call

Condition: used, Year of construction: 2004, operating hours: 5,000 h, Used revised Filling Monoblok MBF 50.70.12.10 17000 bph

Cob Eh Dovgvansnzorb

Production of MBF filling machinery: 14,000 BPH 750 ml with inert gas injection. 17,000 BPH 750 ml without inert gas injection

Equipment of MBF filling machinery: 750 ml bottle with satin cork and 500 ml with crown cap

50 gripper rinsing carousel, fixed nozzle, recirculation system

70 valves light empty filling carousel external diameter 15 mm, centralized adjustment, inert gas injection, automatic CIP to be annex with separate deal.

First 12-head capping carousel for 24x38H and 24x45H cork satin corks, dust extraction, cap feeder (automatic electro-pneumatic coupling / release)

Second 10-head capping carousel for 26 crown caps, magnetic cap elevator (automatic electro-pneumatic engagement / release)

Listing

Fumane (Verona)

Fumane (Verona)

8,269 km

Capping Machine

AVETAPPATORE 6T

Call

Condition: used, Year of construction: 2012, operating hours: 10,000 h, Used Capping Machine AVE 6T up to 7000 bph

The used capping machine AVE 6T up to 7000 bph delivers high efficiency and versatility for the bottling industry. Specifically, it handles medium to high-speed production lines, ensuring consistent and reliable results. Furthermore, the machine for Stelvin Lux uses six capping heads to provide precise and uniform operation throughout every bottling cycle. Moreover, its design maximizes production speed, enabling the handling of up to 7000 bottles per hour. This performance, in turn, supports businesses aiming to improve operational efficiency and maintain consistent product quality.

Crsb Ejvgvabjh Dnzsb

The system supports aluminum screw caps of the Stelvin Lux type, measuring 30×60 mm. Consequently, this cap type creates an airtight seal, preserving product integrity and extending shelf life. Producers in the wine and beverage industry often choose this format for its reliability. Additionally, the machine rotates clockwise, aligning with standard bottling line layouts and reducing the need for costly modifications. Its compact design, moreover, integrates smoothly into existing production environments, even when space is tight.

Safety Features and User-Friendly Maintenance

The used capping machine AVE 6T up to 7000 bp enhances safety by incorporating advanced protective features. For instance, these systems shield operators from potential risks, reducing accidents and improving workplace safety. Furthermore, the safety mechanisms allow operators to access and maintain them quickly, ensuring consistent compliance with industry standards.

The technical manuals of Stelvin Lux, in addition, offer clear instructions for installation, maintenance, and troubleshooting. These guides, therefore, enable operators to resolve issues efficiently, minimizing downtime and preserving productivity. Additionally, the machine’s modular design allows technicians to replace components quickly, streamlining maintenance tasks and lowering repair costs.

Current State and Electrical Requirements

The machine for Stelvin Lux currently remains in storage, ready for immediate installation on a new production line. Moreover, it operates at 400 V, with a power requirement of 3 kW and a frequency of 5 Hz. Therefore, users should verify these specifications to confirm compatibility with their existing electrical systems. Furthermore, the machine’s low energy consumption supports production facilities in reducing operational costs without compromising performance.

Robust Performance and Durability of Stelvin Lux

Thi machine withstands demanding production environments with its durable construction. Notably, its six capping heads ensure consistent quality in every operation, maintaining high production standards. Consequently, businesses rely on this machine to meet ambitious production goals while preserving the integrity of their products. Moreover, its precision and efficiency make it a valuable asset for any bottling operation.

Listing

Fumane (Verona)

Fumane (Verona)

8,269 km

Capping Machine

BertolasoDELTA 596

Call

Condition: used, Year of construction: 1993, operating hours: 920 h, Used Capping Machine Bertolaso DELTA 596 – 7000 BPH

For various types of bottles, 0.75, from the light, heavy, and burgundy to Bordeaux-type bottle.

The classic straight cap can be used up to 28.40 mm.

From the mechanical feeder, the caps reach the capper through a tube that can be easily disassembled and cleaned. The end of the tube is provided with micrometric adjustment, which allows using all the caps having a diameter between 21 and 32 mm. Thanks to this adjustment and to the Bertolaso system for the guided insertion of the caps, they arrive in the best position to the compression group for a correct capping.

Crob Eh Dnjvgu Ahezjb

Listing

Fumane (Verona)

Fumane (Verona)

8,269 km

Filling Machine

BertolasoSuprema 48

Call

Condition: used, Year of construction: 2021, Used isobaric filler Machine Bertolaso 11000 bph

year of the remark of isobaric filler 2021

suitable for bottling sparkling and semi-sparkling wines

entrance on the left

completely overhauled isobaric filler in all its parts with original Bertolaso spare parts (documentable)

bottle sizes 85, 88, 90, 112

6 sets of channels with isobaric filler to make the levels

the electrical panel of the Used Isobaric Filling Machine according to CE standards

use and maintenance manual, spare parts manual available for this isobaric filler

the production speed of isobaric filler is 9000 BPH with the sparkling wine

the production speed is 7000 BPH with spumante.

This isobaric filler is immediately available and delivered in case of purchase. We can assist the buyer in each step of the commissioning and testing operation of the Used Isobaric Filling Machine.

How to build one isobaric triblock:

The isobaric filler can be connected either to an automatic rinsing machine or to one or more cappers.

We have 40 Bertolaso SBR grippers and two series of Bertolaso mushroom and satin cappers.

One has 6 heads and reaches 9.000b / h, and one has 10 heads and reaches 14.000 BPH

We can introduce all the machines in a sterile clean room with a filtration system.

You can have the performance of an isobaric triblock with a Used Isobaric Filling Machine for natural cork and mushroom.

Productivity can be from 11,000 to 14,000 BPH.

Crjb Ehjvguv Uo Dnzjb

It is possible to foresee a periodic maintenance program for isobaric filler to always have excellent efficiency. This involves both having spare parts in stock and foreseeing machine stops for a week/10 days.

In case of purchase of the isobaric filler triblock, at least 9.00 meters by 2.50 meters, H 4.00 meters are required. The creation of a clean room guarantees the absence of contamination in the bottling phase.

Trust Seal

Dealers certified through Werktuigen

Listing

Fumane (Verona)

Fumane (Verona)

8,269 km

Depalletizer

AcmiStratos

Call

Condition: used, Year of construction: 2003, Used Depalletizer ACMI Stratos for 7000 b\h for glass bottles:

This used depalletizer has been disassembled in September 2021 but is in perfect condition.

The floor space requirement for it is around 20 m2, complete with a table for round bottle alignment, safety barriers and pallet conveyors.

Cob Esvguv Ieh Dnzsrb

This used depalletizer is automatic, i. e. human intervention is only needed in the beginning to introduce the pallet of empty bottles into the appropriate space.

Only the cutting of the film that wraps the bottles and removing the plastic interlayer separator is required.

After this the machine picks up an entire layer of empty bottles and lifts them and moves them all together and deposits them on the connected automatic bottle extraction table.

This is all motorized and synchronized with the movement of the depalletizer during unloading.

In order to it is used to align the bottles coming out of the used depalletizer for sale then channel them on the motorized conveyor belts.

This whole procedure of the ACMI Depalletizer is controlled by a software program that guides all the unloading phases of the empty glass bottles.

All moving parts are protected by anti-intrusion barriers to prevent operators from entering during the processing cycle.

This is achieved both by barriers physically placed for protection and by barriers created with the aid of photocells.

However, these create a safety perimeter where if an operator enters without disarming them, the safety devices are triggered and the automatic depalletizer disconnects from the movement all the parts so the worker is safe.

There are no automated conveyors for loading pallets full of empty bottles but they can possibly be added.

In this case, an addition to the PLC of the used depalletizer automatic and to the program must be made.

Listing

Fumane (Verona)

Fumane (Verona)

8,269 km

Complete Bottling Line

Call

Condition: used, operating hours: 24,000 h, Used Bottling Line for Sale Bertolaso 7000 BPH – 1999 for still and sparkling wine.

The bottling Line for Sale as a whole, considering every component, is very well maintained. Clean and without obvious or compromising signs of wear. The sparkling wine bottling line reaches an hourly speed of about 3000 BPH on the 0.75 formats.

Depalletizer:

The line starts with the Acmi automatic depalletizer model Rasar P130; with an electric roller pallet storage that manages the pallets automatically with two pallets waiting. The maximum height of the workable pallet can reach about 2 meters. The standard pallet size is 800 × 1200 with a height of 140 cm. Automatic inter-layer remover with compressed air rotating arm. It has a parachute safety system that prevents the head from going down in case there is an operator. It is also equipped with a perimeter barrier that blocks the machine in case the doors are opened.

Filling Isobaric Monoblock of Bertolaso Bottling Line for Sale:

The Bertolaso Sincronia 1400 filling monoblock starts with a 28-valve internal bottle rinsing machine followed by an isobaric filler with 36 taps and ends with a 6-head mushroom cork corker, or a 4-head screw cap. It has a machine pitch of about 30 cm to allow the processing of multiple formats of different sizes. The direction is clockwise.

Safeguards are all present as also machine manuals. This line’s bottled product is wine and sparkling wine in sizes from 0.375 to 1.5 L.

It performs isobaric filling with mobile nozzles and traditional valves. It generates a vacuum before capping.

The type of cap used is cork (straight or mushroom) or silicone with 6 heads; while aluminium and Stelvin caps with 4 heads. The size of the corker ranges from a minimum of 44 × 23.5 to 48 × 30.5 mm.

Inspector:

It is a 2011 model that is able to check the level and the cap, the internal product and any residues inside the empty bottle. Fully electronic with laser sensors, it can work at a speed of 7000 BPH and over.

Washer-dryer:

It’s a Cames from 2000 with a spray washing system that rinses the bottle externally, brushes it and then passes it under the hot air hair dryers that immediately dry the bottle preparing the surface for labelling.

Creb Ehjvguu Ds Dnzsb

Wirehooder and Capsule:

Next in line is a Spumante Wirehooder of the brand Nortan Minerva 60, an accumulation space for the bottles followed by a Nortan capper. It is also suitable for sparkling wines with centring, with a maximum height of the processed bottle ranging from 15 to 35 cm.

Overall mass 3000 kg; Consumption: 380 v, 15 kW, 50 Hz

Labelling machine:

Bertolaso Bottling Line for Sale has a Krones labeller from the year 2000 with a bottle lock at the entrance. It has 8 plates with a machine pitch of about 30 cm. It has a manual head and glue film adjustment, mechanical centring system and outgoing label smoothing.

Listing

Fumane (Verona)

Fumane (Verona)

8,269 km

Capping Machine

ArolKAMMA PK

Call

Condition: used, Year of construction: 1999, Used Capping Machine AROL KAMMA year 1999

Introduction to the AROL KAMMA 1999 Capping Machine

Initially, the Used capper AROL KAMMA capping machine, launched in 1999, symbolizes efficiency and precision in packaging. Remarkably, it processes up to 7000 bottles per hour (BPH), exemplifying high productivity. Its design, notably featuring six capping heads, not only promotes high throughput but also ensures versatility. Furthermore, the machine’s ability to handle T-caps expands its use across various formats, making it an indispensable asset in bottling.

Advanced Functionality for Optimal Performance

Significantly, this specific capper is marked by advanced features. Its adjustable-height capping head, a key element, allows adaptation to different bottle sizes and shapes. Consequently, this flexibility maintains consistent capping quality across production lines. Moreover, the cap distribution system, using an innovative cellular centrifugal distributor, guarantees a steady cap supply. This aspect is essential for maintaining the impressive 7000 BPH output, ensuring uninterrupted production.

Safety Features and Robust Design

In terms of safety, the AROL KAMMA is exceptionally well-equipped. It includes comprehensive safety measures to prevent accidents and protect operators. Additionally, its construction with high-grade stainless steel isn’t just durable; it also eases cleaning and maintenance. This robust design is vital for continuous operation at high speeds, especially crucial given the substantial 7000 BPH output.

Cjb Eh Dnevgt T Eezsrb

Operational Flexibility and Efficiency

Regarding operational flexibility, the AROL KAMMA excels. Its speed can be precisely adjusted using an inverter, allowing pace customization for specific production needs. This adaptability ensures seamless integration into various bottling lines with differing speeds and configurations. Also, the bottle entry, designed for left-hand (clockwise) flow, fits a wide range of production setups.

Conclusion

To conclude, the 1999 KAMMA capping machine, capable of handling 7000 BPH, is a superior choice for demanding bottling needs. It combines speed, precision, adaptability, and safety, making it essential for businesses aiming to boost bottling efficiency and reliability. Lastly, the machine’s lasting design and advanced technology make it a wise investment for companies.

Listing

Fumane (Verona)

Fumane (Verona)

8,269 km

Wrap Around Packer

VANTAWSD-B352

Call

Condition: used, Year of construction: 2014, Used Automatic Wrap Around Packer Vanta 2100 bph

Introductionof the Wrap Around Packer Vanta

Initially, the used Vanta 2100 bph automatic wrap around packer marks a significant innovation in the bottling sector. Specifically designed to accommodate various container types like cans, glass bottles, and PET bottles, this machine exemplifies efficiency and precision in packaging.

Ceb Ehovgt Tre Dnzjrb

Product Types and Scope of Application

Notably versatile, the Vanta 2100 bph adeptly adapts to different product sizes and types. It can manage cans, glass, and PET bottles, with diameters ranging from 50 to 110mm and heights from 70 to 370mm. Moreover, its capacity extends to the packaging size, crosswise to the conveyor direction from 140 to 450mm, and forward from 200 to 450mm. Additionally, the range for corrugated board sizes is expansive, horizontally to the conveying direction from 210 to 1500mm, and frontally from 280 to 700mm.

Technical Specifications

Functionally, the machine operates with a three-phase voltage of 380V and a frequency of 50 Hz. Its power consumption is a modest 13 KW, while control is efficiently maintained at 24VDC. Regarding air usage, it’s a critical aspect, with a consumption of 110L/min at 0.6MPa and 6.7 m3/h. Weighing 7000 Kg, it conforms to noise regulations, maintaining a level within 85 dB.

Positioning and Feeding

For carton feeding, the setup is straightforward, ensuring a consistent and smooth material flow. This feature is crucial for maintaining efficiency and reducing downtime, assuring that each packaging phase is seamless and uninterrupted.

Conclusionof the Wrap Around Packer Vanta

In summary, the Used Automatic Wrap Around Packer Vanta 2100 bph stands as an optimal solution for the packaging of cans, glass, and PET bottles. With advanced technical specifications and the ability to handle diverse product and packaging sizes, this machine offers unmatched value in the bottling industry, blending versatility, efficiency, and precision into one comprehensive tool.

We make it easier for you to find: "barford sxr 7000"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Barford Sxr 7000 (1,258)

Search Werktuigen now with more than 200,000 used machines:

Find out now

+49 201 857 86 180

+49 201 857 86 180

Create listing

*per listing / month