Used Schaffer 5050 Z for sale (11,407)

Sort results

- Lowest price Highest price

- Latest listings Oldest listings

- Shortest distance Farthest distance

- Latest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Latest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Latest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation A to Z

- Designation

- designation Z to A

- Designation

- Model A to Z

- Model

- Model Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest running time

- Runtime

- Relevance

- Relevance

Auction

Ends in

d

h

min

s

Auction ended

Baden-Württemberg

Baden-Württemberg

7,934 km

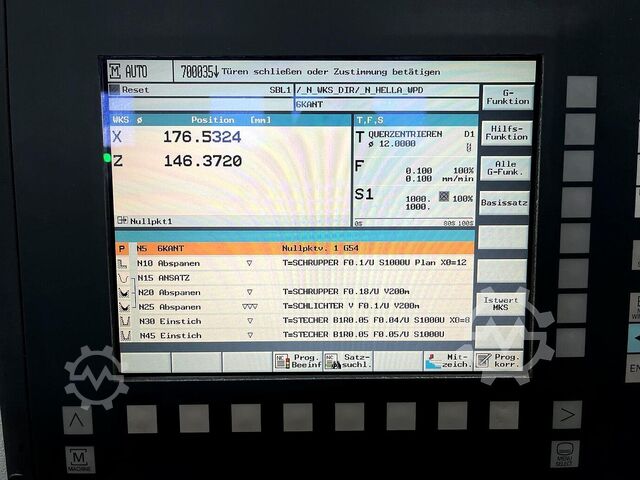

CNC lathe

EMCOTURN 365 TCMY

Condition: good (used), Year of construction: 2002, Functionality: fully functional, machine/vehicle number: R6CQ2401, turning diameter over cross slide: 360 mm, spindle bore: 65 mm, spindle speed (max.): 4,000 rpm, travel distance X-axis: 210 mm, travel distance Z-axis: 610 mm, No reserve price - guaranteed sale at the highest bid!

TECHNICAL DETAILS

Control: Siemens Sinumerik 840 D

X-axis travel: 210 mm

Z-axis travel: 610 mm

Z-axis in rotary axis – resolution: 0.001°

Spindle

Spindle size: 65 mm diameter

Outer spindle diameter of front bearing: 100 mm

Swing diameter over bed: 600 mm

Swing diameter over cross slide: 360 mm

Distances and workpiece sizes

Distance between main spindle and tailstock: 805 mm

Distance between main spindle and counter spindle: 716 mm

Max. workpiece size with tailstock: 200 × 520 mm diameter

Counter spindle / tailstock

Internal taper of counter spindle/tailstock: MK4

Tailstock travel: 500 mm

Max. clamping force: 8,000 Nm

Feed and Rapid traverse

Feed force X/Z-axis: 5,000–7,000 Nm

Rapid traverse X-axis: 24 m/min

Rapid traverse Z-axis: 24 m/min

Rapid traverse: 100 rpm

Tool carrier

Tool turret: 12-station

Tool holder: VDI 30

Driven stations: 12

Speed range of driven tools: 0–4,000 rpm

Dksln E Towd R Nwj R Njl

MACHINE DETAILS

Dimensions: 4.0 x 2.5 x 2.5 m

Weight: 6 t

Operating voltage: 400 V

Frequency: 50–60 Hz

Rated current: 29 A

EQUIPMENT

- SCHUNK three-jaw chuck with 220 mm diameter

- Tailstock included

- Machine can be transported on a standard truck

Auction

Ends in

d

h

min

s

Auction ended

Vestland

Vestland

7,054 km

Horizontal machining center

MazakPFH 4800

Condition: ready for operation (used), Year of construction: 2005, Functionality: fully functional, machine/vehicle number: 181756, travel distance X-axis: 560 mm, travel distance Y-axis: 630 mm, travel distance Z-axis: 600 mm, controller model: Mazatrol 640M, number of slots in tool magazine: 40, Machine is delivered EXW - free on truck.

TECHNICAL DETAILS

X-axis travel: 560 mm

Y-axis travel: 630 mm

Z-axis travel: 600 mm

Distance from pallet to spindle center: 80 – 710 mm

Distance from pallet center to spindle nose: 70 – 670 mm

Table

Pallet size: 400 mm x 400 mm

Pallet load (uniform): 400 kg

Pallet surface: M16 × P2

Indexing time: 1.3 s / 90°

Feed

Rapid traverse: 60,000 mm/min

Feed rate: 1 – 60,000 mm/min

Tool changer

Tool holder: CAT No. 40

Tool magazine capacity: 40 tools

Max. tool diameter / length / weight: 95 mm / 360 mm / 12 kg

Tool diameter with free adjacent tool position: 150 mm

Tool change time (chip-to-chip): 2.2 s

Change method: random/shortest path

Pallet change time: 5 s

Number of pallets: 2

Coolant

Coolant pump: 0.75 kW

Coolant tank volume: 500 l

Dksln E Towgdnxs R Nsl

MACHINE DETAILS

Footprint (L × W): 2,435 × 4,244 mm

Machine height: 2,794 mm

Machine weight: 11,400 kg

Connected load: 66 kVA

EQUIPMENT

- Rotating pallet changer (5 sec. pallet change time)

- 2 pallets

- Chip conveyor

- Manuals

High-speed spindle (under test)

Speed range: 35 – 15,000 rpm

Spindle gearbox: 1

Motor power (15 min. / continuous): 30 kW / 22 kW

Tool holder: 7/24 taper No. 40

High-torque spindle (tested)

Speed range: 35 – 12,000 rpm

Spindle gear: 1

Motor power (15 min. / continuous): 22 kW / 15 kW

Tool holder: 7/24 taper No. 40

Auction

Ends in

d

h

min

s

Auction ended

Nordrhein-Westfalen

Nordrhein-Westfalen

7,693 km

3D Printer

StratasysObjet 500 Dental Solution

Condition: excellent (used), Year of construction: 2018, operating hours: 25,200 h, Functionality: fully functional, machine/vehicle number: 530021, No reserve price - guaranteed sale at the highest bid!

TECHNICAL DETAILS

Maximum build volume: 490 × 390 × 200 mm

Maximum number of materials per part: 82

Support material: SUP705 / SUP706 (soluble)

Horizontal layer thickness: 16 μm

Resolution and accuracy

X-axis resolution: 600 dpi

Y-axis resolution: 600 dpi

Z-axis resolution: 1,600 dpi

Resolutions by print mode

Digital materials: 30 μm

High quality: 16 μm

High speed: 30 μm

Software and compatibility

Software: Objet Studio™, compatible with GrabCAD Print

Dkjln E T Rjwhllzs Nsl

Workstation compatibility: Windows 7 / Windows 8

MACHINE DETAILS

Device dimensions: 1,400 × 1,260 × 1,100 mm

Device weight: 430 kg

Material cabinet size: 330 × 1,170 × 640 mm

Material cabinet weight: 76 kg

Operating environment and power supply

Temperature range: 18 to 25 °C

Humidity: 30–70% (non-condensing)

Power requirement: 110 to 240 VAC, 50/60 Hz, 1.5 kW, single-phase

EQUIPMENT

- LAN network connection TCP/IP

- CE/FCC approval

Machine has been regularly serviced by the manufacturer

Find out now

+49 201 857 86 180

+49 201 857 86 180

Create listing

*per listing / month

Listing

United States

United States

0 km

CNC Turning- and Milling Center

INDEXG 250

Call

Condition: used, Year of construction: 2016, swing diameter 560 mm

turning length 1.400 mm

control C200-4D Siemens 840 D

spindle head 8 DIN 55026/55021 ISO 7027/1

bar capacity 90 mm

spindle diameter in front bearing 140 mm

turning speed range - spindle ~ 3.500 U/min

drive capacity - spindle motor 100% / 40%: 43 / 57 kW

Torque 275 / 363 Nm

Indexing 2,5 °

C-Axis 0,001 °

spindle head 6 DIN 55026/55021 ISO 702/1

bar capacity 65 mm

spindle diameter in front bearing 110 mm

turning speed range - spindle ~ 5.000 U/min

drive capacity - spindle motor 100% / 40%: 43 / 57 kW

Torque 275 / 363 Nm

Indexing 2,5 °

C - Axis 0,001 °

Number of Turrets 3

turret (x-stations) 3 x 12 pos

number of toolpositions 12 pos.

Spindle speed - driven tool stations ~ 6.000 min -1

Dkoln Eewb Hx Ao T R Nsl

power capacity - driven tool-stations 11 kW

tool taper 30 x 55 mm DIN 69880

Torque 21,5 Nm

travel -x axis 300 mm

travel -y axis 190 mm

travel -z axis 1.400 mm

b - axis 360 °

Holding Torque B: 3.000 Nm

rapid traverse X/Y/Z: 20 / 10 / 40 m/min

rapid traverse B: 360 °/sec

feed power X/Z: 9.000 N

feed power Y: 16.000 N

number of toolpositions 12 pos.

Spindle speed - driven tool stations ~ 6.000 min -1

power capacity - driven tool-stations 9,4 kW

Torque 19 Nm

travel -x axis 140 mm

travel -z axis 1.375 mm

rapid traverse X-axis 22,5 m/min

rapid traverse Z-axis 45 m/min

feed power X/Z: 9.000 N

number of toolpositions 12 pos.

Spindle speed - driven tool stations ~ 6.000 min -1

power capacity - driven tool-stations 11 kW

tool taper 30 x 55 mm DIN 69880

Torque 21,5 Nm

travel -x axis 300 mm

travel -y axis 190 mm

travel -z axis 1.400 mm

b - axis 360 °

Holding Torque B: 3.000 Nm

rapid traverse X/Y/Z: 20 / 10 / 40 m/min

rapid traverse B: 360 °/sec

feed power X/Z: 9.000 N

feed power Y: 16.000 N

tool taper 30 x 55 mm DIN 69880

total power requirement 108 kVA

weight of the machine ca. 14 t

dimensions of the machine ca. 8,0 x 2,6 x 2,5 m

CNC Turning- and Milling Center

INDEX G 250

- INDEX WHD 200/14 Workpiece Handling System

Chuck parts max. 200 mm in diameter

Length up to approx. 200 mm

Shaft parts max. 80 mm in diameter

Length up to approx. 400 mm

Workpiece weight max. 2x 10 kg

Max. workpiece projection: 150 mm (at 10 kg)

Two-jaw double gripper for blanks and finished parts

Longitudinal gripper travel Z: max. 5,200 mm

Gripping stroke Y: max. 300 mm

Electric rotation axis 23 degrees

Electric gripper rotation angle horizontal axis 4x 90 degrees

Double gripper travel per gripper jaw 20 mm

- Schnaithmann Pallet Handling System (Type BS)

20x workpiece carriers 240 x 200 mm

Listing

United States

United States

0 km

Multi-Spindle Turning Machine

DMG MORIMultisprint 36

Call

Condition: ready for operation (used), Year of construction: 2019, Control Unit

Brand FANUC

Model 30i-B

Main Drive

Number of axis 12

Movement

X-Axis Movement 50 mm

Y-Axis Movement 50 mm

Z-Axis Movement 100 mm

Turret

Number of turrets 1

Additional Equipment

Chip Conveyor, Hinged Type

High Pressure Device: 0.25/5/12 MPa

Dslnev Dni Ao E T R Nskl

Oil Mist Collector for Oil/Emulsion

Chiller System for Machine & High Pressure Device

Cooling

This 12-axis DMG MORI Multisprint 36 multi-spindle turning machine was manufactured in 2019. Ideal for complex turning operations, it offers precision and efficiency. If you are looking to get high-quality turning capabilities, consider the DMG MORI Multisprint 36 machine we have for sale. Contact us for more information.

Application Types

Turning

Listing

St. Charles

St. Charles

829 km

Center Hole Grinding Machine

TechnicaZentroflex 14-SA-110 (CNC Control)

Call

Condition: new, Year of construction: 2025, Functionality: fully functional, workpiece weight (max.): 170 kg, grinding spindle speed: 45,000 rpm, spindle speed (min.): 5,000 rpm, spindle speed (max.): 45,000 rpm, clamping diameter: 140 mm, clamping length: 1,100 mm, warranty duration: 12 months, Workpiece Clamping Diameter : ø 3 – 140 mm

Workpiece Length : 50 – 1.100 mm

Centre Hole Diameter : ø 1 – 100 mm

Workpiece Weight : max. 170 kg

Center Hole Angle : 60 °

Accuracy : < 1 µm (Submicron accuracy)

Spindle Speed : 5.000 – 45.000 rpm

Grinding Cone Movements : 3+1

Rotation

Orbital rotation

Stroke movement

+1 Workpeice rotation

Quirlig Grinding Technique : Included (Cross-hatched grinding pattern)

Grinding Process : Semi-Automatic, CNC

Control Panel : Beckhoff

CNC Movements : Z-Axis

Indurstry 4.0 Compatibility : Available

Semi-Auto Grinding Cone Dressing : Included

Workpiece Rotation : Available (as a option)

Dust Extraction And Filtration : Available (as a option)

Sectors : Precision Grinding, Aviation, Automotive, Machinery etc.

Benefits:

Sub-micron Precision: Achieve sub-micron (< 1 µm) precision in grinding thanks to Swiss engineering and a robust machine design.

Sustainable Reliability: Ensure reliable and sustainable processing.

Cost Efficiency & High Productivity: Benefit from lower production costs and high productivity due to a short grinding process and reduced production times for subsequent processes (cylindrical grinding).

Quirlig Grinding Technique: Experience an optimized grinding process with the Quirlig Grinding Technique. Properly ground center holes that have cross-hatched grinding pattern. The cross-hatched grinding pattern ensures that oil is retained when the workpiece is placed between the centers during the cylindrical grinding process, creating a micro oil layer. The micro oil layer prevents unwanted "dry running" during cylindrical grinding.

Easy to Use CNC Control Panel: Benefit from very simple operation and grinding program recording with the Beckhoff control panel and Z-axis servo movement.

Dkelewhi Srsn E T R Nel

Industry 4.0: Fully compatible with Industry 4.0 applications, thanks to the Beckhoff control panel.

Low Maintenance Costs: Enjoy low maintenance costs throughout the machine's service life, thanks to Swiss-quality construction.

The Zentroflex SA-series center hole grinding machines are designed to deliver high-precision cylindrical grinding in the aviation, automotive, and machinery sectors. Additionally, the Zentroflex SA-series is the ideal solution for recovering parts distorted after heat treatment or for reducing cylindrical grinding costs.

Z-Axis movement is provided by servo motor in CNC form. The part is loaded-unloaded and clamped manually. Settings are made from CNC control panel and grinding is started by pressing the start button. No other manual setting or control is made during grinding.

Contact us for more details.

Auction

Ends in

d

h

min

s

Auction ended

Baden-Württemberg

Baden-Württemberg

7,934 km

CNC turn-mill center

CHIRONFZ 12 MT Magnum

Condition: good (used), Year of construction: 2014, Functionality: fully functional, machine/vehicle number: 300-01, spindle speed (max.): 12,000 rpm, travel distance X-axis: 550 mm, travel distance Y-axis: 320 mm, travel distance Z-axis: 425 mm, number of slots in tool magazine: 108, swivel angle B-axis (max.): 101 °, TECHNICAL DETAILS

Control system: Siemens Sinumerik 840 D

X-axis travel: 550 mm

Y-axis travel: 320 mm

Z-axis travel: 425 mm

B1 swivel axis: 101°

BT axis: 0 – 180°

V-axis within work area: -40 to -496 mm

V-axis outside work area: up to 570 mm

Z-axis (rotary axis): approx. 450 mm

Spindle data

Main spindle speed: 12,000 rpm

Turning spindle: 4,000 rpm

C-axis: 6,500 rpm

A-axis: 4,500 rpm

Driven tool speed: 4,500 rpm

Dsln E Tjwd R Exj R Nokl

Tool holder

Main spindle tool holder: HSKA 63

Turret tool holder: Capto 4

Tool holder diameter: 63 mm

Tool magazine

Tool turret: 12-station with driven tools

Tool changer: 32-station

Additional magazine: 64-station

MACHINE DETAILS

Operating voltage: 400 V

Frequency: 50 – 60 Hz

Rated current: 125 A

Connected load: 70 kVA

Dimensions and weight

Installation dimensions (L x W x H): 8,565 x 5,150 x 2,750 mm

Total weight: 18,000 kg

EQUIPMENT

- Coolant system

- Breuning Simag bar loader, built in 2014

- Tool measuring system

- Internal cooling system with 70 bar internal cooling

- Driven safety door

- Technical documentation

- Manual

- Continuously adjustable speed

- Transport on a standard truck possible

Listing

Oak Forest

Oak Forest

851 km

Turning automatic lathe

TORNOSMultiSwiss 6x16

Call

Condition: excellent (used), Year of construction: 2016, Tornos MultiSwiss 6x16

CNC Multi-Spindle Screw Machine

Dkeln E Tswb H Tto R Nel

Mfd. 2016

6 Spindles

Diameter:16mm.

Fanuc Control

Equipped as pictured

Run time: 41786 hrs

Power on: 64,164 hrs

Standard tornos bar feed (5ft)

6 Motorspindles 5,5 kW max. speed 8’000 RPM

Spindle capacity 14 mm, Z 50mm stroke

(max. parts 40mm).

6 slides X 40mm stroke

1 counter-operation slide, 75mm stroke.

Counter spindle with integrated motor 6 kW

Max. speed 8’000 RPM, 150mm stroke.

Numeric control Fanuc 30i

Integrated PC with screen 17”

Programming system TB DECO

(DCS version)

(requires 3001)

contact us for more detail

Listing

Idaho

Idaho

1,123 km

Cnc lathe

HEMBRUGMikroturn 100 CNC

Call

Condition: excellent (used), Year of construction: 2004, operating hours: 1,000 h, Functionality: fully functional, turning diameter over cross slide: 380 mm, turning length: 350 mm, turning diameter: 200 mm, travel distance X-axis: 240 mm, rapid traverse X-axis: 12 m/min, Hembrug Mill-Turn Machine

Model: Slantbed Mikroturn 100 CNC

Siemens 840D Control

Approximate Actual Run Time Hours: 1,000

Hydeostatic Spindle

Hydrostatic Ways

Scale Feedback

Suspended Granite Bed

Garnite Spindle Housing

Coolant Pump

Coolant Circulation Pump

Pneumatic Bearing Purge

Hydraulic Temperature Control

Coolant Temperature Control

Return Oil Pump and Reservoir for Remote Location of Hydraulic / Cooling Unit.

Options & Additional Purchased Features:

Tailstock

Vacuum Pump for Vacuum Chucking

Programable Controlled Spray Mist

C-Axis Milling / Drilling

Renishaw Tool Touch Probe

Non-Contact Tool

Incoming Air Dryer / Filter

Thousands of Dollars of Brand New Tooling:

Live Center

Tailstock Taper Adapter

8” Micro-Centric Pneumatic Chuck

3 Sauter Straight Live tooling heads

2 Sauter 90 degree Live tooling heads

1 Special VDI offset Tooling holder

Dksln Eswcfgbo T R Nel

16 VDI Tool Holders for Turning, boring, and on center drilling.

Tool Pick-up Video System

Additional Backup Hard Drive with Software Fully Loaded and Tested.

Extra Siemens Control Pannel

Complete Set of Manuals

Machine Upgrades I added at additional cost.

New Digital Hard Drive

New Backup Hard Drive with software already loaded, plug and play ready, no downtime.

New Z-Axis Heidenhain Scale

Rewound Hydraulic Pump Motor, factory motor was running too hot for my liking.

Replaced Operator Panel, back light on monitor went out, have the original, back light needs replacing.

50 Foot Extended Wiring Harness For Remote Location of Hydraulic / Cooling Unit.

Listing

Canada

Canada

2,464 km

Gear Testing Machine

KLINGELNBERG-OERLIKONCS 200

Call

Condition: good (used), Year of construction: 2004, Clampable cutter head type (max.) 460 mm

Cutter head weight (max.) 150 kg

Mounting disc diameter for cutter heads (Ø) 360 mm

Mounting cone for cutter heads Nominal diameter Ø 58,227 mm

travel -z axis 200 mm

diagram-drawing enlargement ±10 - ± 500 µm

weight of the machine ca. 2,3 t

dimensions of the machine ca. 2 x 1,5 x 2,03 m

In the manufacturing process for spiral-toothed bevel gears, the quality of the

gear cutting gear cutting tools used plays a decisive role. Particularly in

Djljul Efmon E T R Njkl

high gear cutting quality and a long service life can only be achieved with

precisely can only be achieved with precisely adjusted cutterheads.

The Oerlikon cutterhead setting and testing device CS 200 enables quick and

easy setting of the individual knives and simple adjustment of the individual

knives, it checks the position and documents the measurement results. The

measuring sequence on the CNC-controlled testing device is partially automated:

The individual actions for carrying out the actions for carrying out the

sequence are displayed on the screen via the operator guidance. The positioning

of the individual knives in the cutter head and the height of the knife tips is

largely automatic thanks to a special sequence and is simultaneously documented

by means of a run-out diagram. A subsequent measuring sequence checks the

radial position of the inner and outer cutting edges of all knives in the

cutterhead. If individual test parameters on the knives do not correspond to the

the tolerance specifications, this can be individually repositioned. The

combination of semi-automated setting sequence, operator-guided set-up actions

and automatic operator-guided set-up actions and automatic measuring sequence,

cutterheads can be can be set conveniently, quickly and with high precision.

Operator-guided setting and test sequence

- Graphic display of the cutter head design and the measurement results with

tolerance check

- Instructions for the operator in plain text Instructions for the operator in

plain text (without coded information)

- Simple assignment of the measurement results to the knives

- Documentation of the setting and measurement results via printer- Setting and

test sequence suitable for ARCON®, RSR, Spirapid, SPIRON®, TRI-AC® types

- Interface for neutral data

Listing

Canada

Canada

2,264 km

Vertical Machining Centre

MazakVCN 700E/40-II

Call

Condition: ready for operation (used), Year of construction: 2013, General Data

Machine weight 12020 kg

Control Unit

Brand MAZATROL

Movement

Doln E Tewfuqus R Nekl

X-Axis Movement 203.2

Y-Axis Movement 70.10

Z-Axis Movement 71.8

Additional Equipment

Tool Taper: CAT#40 / Automatic Tool Changer (ATC): 48 tools

This 3-axis Mazak VCN 700E/40-II vertical machining center was manufactured in 2013. Ideal for precision engineering, it offers robust construction and reliable performance. Consider the opportunity to buy this Mazak VCN 700E/40-II vertical machining center. Contact us for more information.

Application Types

Milling

Auction

Ends in

d

h

min

s

Auction ended

Baden-Württemberg

Baden-Württemberg

7,934 km

5-axis machining center

Deckel MahoDMF 220 linear

Condition: good (used), Year of construction: 2004, operating hours: 5,012 h, Functionality: limited functionality, machine/vehicle number: 15115221654, travel distance X-axis: 2,200 mm, travel distance Y-axis: 560 mm, travel distance Z-axis: 720 mm, spindle speed (max.): 6,300 rpm, number of slots in tool magazine: 100, swivel angle B-axis (min.): -90 °, swivel angle B-axis (max.): 90 °, swivel angle C-axis (max.): 360 °, Note: Minor relay error.

TECHNICAL DETAILS

X-axis travel: 2,200 mm

Y-axis travel: 560 mm

Z-axis travel: 720 mm

Rapid traverse

X-axis rapid traverse: 100 m/min

Y-axis rapid traverse: 50 m/min

Z-axis rapid traverse: 50 m/min

Feed rate

X-axis feed rate: 20 m/min

Y-axis feed rate: 20 m/min

Z-axis feed rate: 20 m/min

Dkoln E Tswd N D Ts R Njl

Table

Table length: 2,600 mm

Table width: 560 mm

T-slots: 6 x 18H7

Table load: 2,200 kg

Spindle

Spindle speed: 20 - 6,300 rpm

Spindle torque: 350 Nm

Spindle power: 14,000 W

Tool holder: 40 mm (SK 40 DIN69871 A)

Max. tool weight: 6,000 g

Tool magazine

Number of magazine positions: 100

Rotary and swivel axes

Rotary table diameter (C-axis): 500 mm

Max. rotation speed (C-axis): 10 rpm

Rotation range (C-axis): 360° (hydraulically clamped)

Swivel range of swivel spindle (B-axis): +90° to -90°

Tilt-action of swivel spindle (B-axis): 2.5°

Accuracy

Position tolerance (X, Y, Z): 0.010 mm

Resolution: 0.001 mm

Control system

Control system manufacturer: SIEMENS

Control system model: Sinumerik 840D

MACHINE DETAILS

Spindle hours: 5,012 h

On-time: 17,969 h

Connected load: 60 kVA

Total length: 6,800 mm

Total width: 3,900 mm

Total height: 2,750 mm

Total weight: 16,000 kg

Transport dimensions: 2.78 x 4.47 x 2.56 m

Transport weight: 14 t

EQUIPMENT

- Chip conveyor

- Continuously adjustable speed

- Technical documentation and manual

- Hydraulically clamped rotary axis

- Tilting spindle with 2.5° indexing

Listing

Oak Forest

Oak Forest

851 km

Turning automatic lathe

TORNOSMultiSwiss 6x16

Call

Condition: excellent (used), Year of construction: 2016, Tornos MultiSwiss 6x16

CNC Multi-Spindle Screw Machine

Mfd. 2016

6 Spindles

Diameter:16mm

Fanuc Control

Equipped as pictured

Run time: 42,689 hrs

Power on: 64,668 hrs

Standard tornos bar feed (5ft)

6 Motorspindles 5,5 kW max. speed 8’000 RPM

Spindle capacity 14 mm, Z 50mm stroke

(max. parts 40mm).

6 slides X 40mm stroke

1 counter-operation slide, 75mm stroke.

Dkeln E Tewa D Tue R Njl

Counter spindle with integrated motor 6 kW

Max. speed 8’000 RPM, 150mm stroke.

Numeric control Fanuc 30i

Integrated PC with screen 17”

Programming system TB DECO

(DCS version)

(requires 3001)

contact us for more details

Listing

Canada

Canada

2,264 km

Horizontal Turning Machine

MazakMultiplex 6300-II Y

Call

Year of construction: 2012, Condition: ready for operation (used), General Data

Measurements width 1000 mm

Measurements depth 1700 mm

Measurements height 870 mm

Machine weight 11974 kg

Control Unit

Brand MAZATROL

Main Drive

Number of spindles 2

Spindle speed range 4000 RPM

Spindle motor power 30 HP

Spindle bore 87,884 mm

Number of axis 3

Movement

X-Axis Movement 309.88

X-Axis Rapid Traverse 945 IPM

Y-Axis Movement 76.2 mm

Z-Axis Movement 605.028 mm

Z-Axis Rapid Traverse 945 IPM

Turret

Number of turrets 2

Rotating tools Yes

Tools

Number of station 12

Additional Equipment

Max Cutting Length (Chucker): 225 mm

Max Distance Between Spindle Faces: 1450 mm

Min Distance Between Spindle Faces: 249.42mm

General Data

Measurements width 1000 mm

Measurements depth 1700 mm

Measurements height 870 mm

Machine weight 11974 kg

Control Unit

Brand MAZATROL

Main Drive

Number of spindles 2

Spindle speed range 4000 RPM

Spindle motor power 30 HP

Spindle bore 87,884 mm

Number of axis 3

Movement

X-Axis Movement 309.88

X-Axis Rapid Traverse 945 IPM

Y-Axis Movement 76.2 mm

Z-Axis Movement 605.028 mm

Z-Axis Rapid Traverse 945 IPM

Turret

Number of turrets 2

Rotating tools Yes

Tools

Number of station 12

Additional Equipment

Max Cutting Length (Chucker): 225 mm

Max Distance Between Spindle Faces: 1450 mm

Min Distance Between Spindle Faces: 249.42mm

This 3-axis Mazak Multiplex 6300-II Y was manufactured in 2012, offering robust capabilities for horizontal turning. Ideal for precision machining, this used machine maintains a solid performance record. Consider the opportunity to buy this Mazak Multiplex 6300-II Y horizontal turning machine. Contact us for more information about this machine.

Application Types

Turning

Dkelnswfurlj E T R Nel

Auction

Ends in

d

h

min

s

Auction ended

Baden-Württemberg

Baden-Württemberg

7,984 km

Vertical machining center

UNITECHXV 450

Condition: ready for operation (used), Year of construction: 2012, Functionality: fully functional, machine/vehicle number: 10700049, travel distance X-axis: 450 mm, travel distance Y-axis: 300 mm, travel distance Z-axis: 320 mm, spindle speed (max.): 10,000 rpm, number of slots in tool magazine: 14, No reserve price - guaranteed sale at the highest bid!

TECHNICAL DETAILS

Control: Siemens Sinumerik 828 D

X-axis travel: 450 mm

Y-axis travel: 300 mm

Z-axis travel: 320 mm

Table

Table length: 500 mm

Table width: 350 mm

Table clamping area: 450 × 300 mm

Table load: 150 kg

Number of T-slots: 3

T-slot spacing: 100 mm

Spindle

Spindle speed: 10,000 rpm

Tool holder: SK 30 / BT 30

Spindle cooling: 25 bar internal cooling

Rapid traverse and feed rate

X-axis rapid traverse: 48 m/min

Y-axis rapid traverse: 48 m/min

Z-axis rapid traverse: 36 m/min

Working feed rate: 12,000 mm/min

Dkjln E T Rowd Sp So Nol

Tool magazine

Tool changer: 14-station

Tool holder included: 20 × SK 30

Max. tool diameter: 90 mm

Max. tool length: 200 mm

Max. tool weight: 3 kg

Chip-to-chip time: 2.8 s

MACHINE DETAILS

Operating voltage: 400 V

Frequency: 50 Hz

Rated current: 20 A

Connected load: 15 kVA

Weight: 2.4 t

EQUIPMENT

- GRUNDFOS coolant pump

- Cooling unit

- 20 SK 30 tool holders included

Listing

Oak Forest

Oak Forest

850 km

Cnc lathe

TraubTNX 65/42

Call

Condition: good (used), Year of construction: 2007, Traub TNX 65/42 Milling and Turning Center

Mfd. 2007

Serial #7060107

Commissioned in 2010

TX 8i-S control (Mitsubishi/Traub based control with Mitsubishi drives and motors)

15 CNC axis’s

(4) X-Y-Z turrets with 10 positions each. Up to 20 tools per turret

65 mm thru hole main and sub spindle (sub spindle has coolant flush)

Foot pedal control for clamp/unclamp of spindle chucks

Servo driven gantry receiver

Hydraulic swivel w/ pneumatic finished part and bar remnant gripper

Finished part conveyor belt

RESY paper band coolant filter

Knoll Coolant tank with BKW refrigerated coolant temperature control

20 Bar High pressure and 8 Bar Low pressure coolant pumps

Knoll chip conveyor

FMB Turbo 5-55 magazine bar feeder (new in 2010)

2) Single stick turning tool holders

2) Double stick turning tool holders

1) Cut-off tool holder

1) Overdriven double radial live ER Collet tool holder

1) Overdriven radial live ER Collet tool holder

4) Radial live ER Collet tool holders

1) Radial live End Mill tool holder

1) Angle adjustable live ER Collet tool holder

2) Radial live Shell Mill tool holders

Dksleq Npqmjn E T R Nol

2) Axial live End Mill tool holders

6) Axial live ER Collet tool holders

43) Additional tool holders on separate list (see supplemental attachment)

Hainbuch main spindle collet chuck

Rohm sub spindle 2 jaw chuck

2 Spare sets of spare Z-axis ball screws and bearing packs.

Listing

Canada

Canada

2,264 km

Horizontal Turning Machine

MazakQTN 250-II

Call

Year of construction: 2009, Condition: ready for operation (used), General Data

Measurements width 1879,6 mm

Measurements depth 2743.2 mm

Measurements height 1905 mm

Machine weight 11000 kg

Control Unit

Brand MAZATROL

Main Drive

Spindle speed range 4000 RPM

Spindle motor power 35 HP

Spindle bore 76.2 mm

Number of axis 2

Movement

X-Axis Movement 177,8 mm

Z-Axis Movement 558,8 mm

Workpiece

Workpiece drm over bed 6731 mm

Turret

Number of turrets 1

Tools

Number of station 12

Dsln E T Rewfuqzs Nskl

This Mazak QTN 250-II was manufactured in 2009. A robust horizontal turning machine, it offers reliable performance for precision machining. Ideal for those looking to enhance their machining capabilities with a proven model. Contact us for more information.

Application Types

Turning

Auction

Ends in

d

h

min

s

Auction ended

Baden-Württemberg

Baden-Württemberg

7,984 km

CNC lathe

SpinnerTC 65 MC

Condition: ready for operation (used), Year of construction: 2007, Functionality: fully functional, machine/vehicle number: AH0366, turning diameter: 310 mm, spindle speed (max.): 4,500 rpm, travel distance X-axis: 230 mm, travel distance Z-axis: 740 mm, bar diameter: 65 mm, No reserve price - guaranteed sale at the highest bid!

TECHNICAL DETAILS

Djln E Tswd Nyzs R Nekl

X-axis travel: 230 mm

Z-axis travel: 740 mm

Turning range

Swing diameter over bed: 425 mm

Max. turning diameter: 310 mm

Center distance: approx. 600 mm

Spindle

Spindle speed: max. 4,500 rpm

Spindle bore: 65 mm

Spindle head diameter: 100 mm

Max. chuck diameter: 250 mm

Max. permissible chuck jaw weight: 1.25 kg

Spindle bearing diameter: 120 mm

Rapid traverse

Rapid traverse X-axis: 15 m/min

Rapid traverse Z-axis: 24 m/min

Tool carrier

Turret stations: 6

Tool holder: DIN 69880 / 30 mm

Speed of rotating tools: max. 6,000 rpm

MACHINE DETAILS

Overall length: 5,000 mm

Overall width: 1,500 mm

Overall height: 1,800 mm

Total weight: 4,700 kg

EQUIPMENT

- LNS Quickload Servo V3 bar loader, built in 2007

- Technical documentation available

- VDI 30 tool holders and machine tools shown are not included in delivery

- Machine without tailstock

Listing

Oak Forest

Oak Forest

851 km

Multi-spindle machine

TORNOSMultiSwiss 6x14

Call

Condition: good (used), Year of construction: 2013, Tornos MultiSwiss 6x14

CNC Multi-Spindle

Mfd. 2013

Capacity: 14mm

6 Motorspindles 5,5 kW max. speed 8’000 RPM

Spindle capacity 14 mm, Z 50mm stroke

(max. parts 40mm).

6 slides X 40mm stroke

1 counter-operation slide, 75mm stroke.

Counter spindle with integrated motor 6 kW

Max. speed 8’000 RPM, 150mm stroke.

Numeric control Fanuc 30i

Doln Esv S Iawo T R Nokl

Integrated PC with screen 17”

Programming system TB DECO

(DCS version)

(requires 3001)

contact us for more details

Auction

Ends in

d

h

min

s

Auction ended

Baden-Württemberg

Baden-Württemberg

7,984 km

Vertical machining center

HURCOVM 10 i

Condition: excellent (used), Year of construction: 2018, Functionality: fully functional, machine/vehicle number: S10-1622378FKBCH, travel distance X-axis: 660 mm, travel distance Y-axis: 406 mm, travel distance Z-axis: 508 mm, spindle speed (max.): 12,000 rpm, number of slots in tool magazine: 20, No reserve price - guaranteed sale at the highest bid!

TECHNICAL DETAILS

X-axis travel: 660 mm

Y-axis travel: 406 mm

Z-axis travel: 508 mm

Table

Table length: 762 mm

Table width: 406 mm

Table load: 682 kg

Table clamping area (L × W): 762 × 406 mm

T-slots (DIN 650): 3 × 18 H8 × 100 mm

Distance spindle nose to table: 102 – 610 mm

Spindle

Max. spindle speed: 12,000 rpm

Spindle power: max. 11 kW

Spindle torque: max. 61 Nm

Tool holder: 40 mm

Speed control: infinitely variable

Feed and rapid traverse

Rapid traverse X-axis: 24 m/min

Rapid traverse Y-axis: 24 m/min

Rapid traverse Z-axis: 24 m/min

Tool magazine

Magazine positions: 20

Delewd Nwyen E T R Nekl

Tool holders (SK40): not included

Tool diameter: 89 mm

Tool length: 250 mm

Tool weight: 7 kg

Accuracy

Positioning accuracy (Pmax.): 0.01 mm

Repeat accuracy (Ps): 0.005 mm

Control system

Control system manufacturer: HURCO

MACHINE DETAILS

Connected load: 15 kVA

Operating voltage: 400 V, 50 Hz

Weight: 2.85 t

Footprint without internal cooling: 3.4 x 3.2 m

Machine dimensions: 2.1 x 1.8 x 2.6 m

Transport dimensions: 1.96 x 2.3 x 2.39 m

EQUIPMENT

- Continuously variable speed Adjustable

- Digital technical documentation can be accessed via the control system

- Without mounted machine vices and the tool holder and tool mounted in the spindle

Listing

Oak Forest

Oak Forest

851 km

Turning automatic lathe

TORNOSMultiSwiss 6x16

Call

Condition: excellent (used), Year of construction: 2019, machine/vehicle number: 14974, Tornos MultiSwiss 6x16

CNC Multi-Spindle Screw Machine

Mfd. 2019

6 Motorspindles 5,5 kW max. speed 8’000 RPM

Spindle capacity 16 mm, Z 50mm stroke

(max. parts 40mm).

6 slides X 40mm stroke

1 counter-operation slide, 75mm stroke.

Counter spindle with integrated motor 6 kW

Max. speed 8’000 RPM, 150mm stroke.

Numeric control Fanuc 30i

Integrated PC with screen 17”

Programming system TB DECO

(DCS version)

(requires 3003)

contact us for more details

Doln E T Rev S H Uyo Njkl

Trust Seal

Dealers certified through Werktuigen

Auction

Ends in

d

h

min

s

Auction ended

Baden-Württemberg

Baden-Württemberg

7,984 km

Rotary transfer machine

EUBAMAS8.1

Condition: ready for operation (used), Functionality: fully functional, machine/vehicle number: 2109, workpiece length (max.): 300 mm, workpiece diameter (max.): 15 mm, No reserve price - guaranteed sale at the highest bid!

TECHNICAL DETAILS

Year of manufacture: probably 1999

Djln E Towd Nq Hs R Njkl

Machining range

Max. diameter to be machined: 15 mm

Min. diameter to be machined: depends on the part

Max. part length: approx. 300 mm

Min. part length: depends on the part

Rotary indexing table

Number of positions: 10 – 12

MACHINE DETAILS

Overall length: 4,000 mm

Overall width: 2,300 mm

Overall height: 2,200 mm

Control voltage: 24 V

Operating voltage: 380 V, 50 Hz

EQUIPMENT

- Knoll coolant cleaning/chip disposal system 240 SF (built in 1990)

- Roller straightener

- Mechanical feed

- Overturning/pre-turning unit

- Gear saw

- Multiple drilling units with rotary indexing table

- Technical documentation

- Manual

Listing

Oak Forest

Oak Forest

851 km

Cylindrical grinding machine

StuderS22

Call

Condition: excellent (used), Year of construction: 2010, machine/vehicle number: 1040-0016, STUDER S22

Cylindrical Grinder (used)

Mfd 2010

Serial #: 1040-0016

with Auto-Load and Fanuc Robot load system,

low hours,

well maintained,

many spares and extra wheels, fixtures, etc.

Available immediately.

It has straight, fixed wheel-head and was set up for OD’s only. It can grind multiple OD’s

simultaneously, but does not do ID’s or faces on the work piece. Ideally suited for a

production environment.

SPECIFICATIONS

SWING: 14"

PLAIN OR ANGLE HEAD: Plain

GRINDING WHEEL DIA.: 24"

CONTROL: CNC (Fanuc)

The S22 is a production platform for the mass production of medium-sized workpieces. It has distances between centres of 650mm (25.6") / 1100mm (43.3") and centre heights of 175mm (6.9") / 225mm (8.8"). It can machine workpieces with a maximum weight of 150kg (330lbs). The S22 with its extensive expansion options can be configured for every grinding application to be the perfect production machine. Highly dynamic axis drives, high-quality STUDER guideway systems, short reaction times and optimized traverses form the basis of the S22. The high-speed grinding option (HSG) contributes to increasing productivity with its peripheral speed of up to 140m/s (27,600 sfpm). Hardware:

GranitanR S103 mineral casting machine base

Cross slide X: anti-friction guideways with ball-screw

Longitudinal slide Z: guideway with patented surface structure and ballscrew drive

C-axis for the workhead

Application-specific workhead concepts

Additional NC axis for profiling the grinding wheel

Full enclosure with movable front panels for optimal accessibility

Integrated loading unit or loading cell for loading and unloading from left, right or above

Large range of accessories

Software:

Easy programming with StuderWIN on Fanuc 31i-A

StuderGRIND programming software to create grinding and dressing programs

Standardized interfaces for loader and peripheral devices

EQUIPPED WITH

Fanuc 31i-A control

Full C Axis work head

24" fixed straight wheel

Auto Load

Fanuc Robot System

Fixtures

Extra Wheels

Djln E Tev Dazwe R Nokl

Spare Parts

Low Hours

Extremely well maintained

Auction

Ends in

d

h

min

s

Auction ended

Baden-Württemberg

Baden-Württemberg

7,984 km

Rotary transfer machine

EUBAMAS8

Condition: ready for operation (used), Year of construction: 1999, Functionality: fully functional, machine/vehicle number: 2685, workpiece length (max.): 300 mm, workpiece diameter (max.): 15 mm, No reserve price - guaranteed sale to the highest bidder!

TECHNICAL DETAILS

Max. diameter to be processed: 15 mm

Min. diameter: depends on the part

Max. part length: approx. 300 mm

Min. part length: depends on the part

MACHINE DETAILS

Control voltage: 24 V

Connection voltage: 400 V, 50 Hz

Dimensions and weight

Total weight: 2,500 kg

Total length: 5,000 mm

Dksln E T Rewd Nlws Njl

Total width: 3,000 mm

Total height: 2,100 mm

EQUIPMENT

- Hydraulic feed

- Gear saw unit

- Rotary indexing table with 20 positions

- Bar feeder

- Technical documentation

- Manual

Auction

Ends in

d

h

min

s

Auction ended

Baden-Württemberg

Baden-Württemberg

7,984 km

Deep hole drilling machine

SFTTBM H8-1-400

Condition: refurbished (used), Year of construction: 2017, operating hours: 428 h, Functionality: fully functional, machine/vehicle number: 428, drilling depth: 400 mm, spindle speed (max.): 23,700 rpm, drill diameter: 6 mm, number of spindles: 1, workpiece length (max.): 450 mm, No reserve price - guaranteed sale to the highest bidder!

Dkeln E T Rjwd Ni As Nel

Machine has only 428 operating hours!

TECHNICAL DETAILS

Control: SFT TBS 200

Drilling method: Single-lip drilling

Number of spindles: 1

Drilling diameter in steel: 1 – 6 mm

Drilling depth with plunge spindle: 120 mm

Drilling depth with sealed housing only: 400 mm

Sealed housing with one-piece steady rest: 350 mm

Max. workpiece length: 450 mm

Max. rapid traverse: 4,000 mm/min

Spindle drive

Power at 2,810 rpm: 2 kW

Power at 7,880 rpm: 3.5 kW

Power at 23,700 rpm: 1.5 kW

Frequency range: 100 – 800 Hz

Tailstock

Motor power: 0.75 kW

Spindle speed: 500 rpm

Max. clamping stroke: 60 mm

Pre-slide drive

Type: Ball screw spindle 25 × 5 mm with servo motor

Drill bushing holder and chip ejector

Drill bushing holder: permanently mounted on the machine bed

Components: BOTEK drill bushing holder and sealing housing

Chip ejection: downwards into the chip container

MACHINE DETAILS

Dimensions: 2.7 x 3.05 x 1.7 m

Weight: 2.5 t

Operating hours: 248 h

Operating voltage: 400 V

Frequency: 50 Hz

Connected load: 14 kW

Coolant system

Tank volume: approx. 500 l

Filtration: integrated paper belt filter

Coolant pump: single-piece with frequency converter

Flow rate: approx. 5 – 12 l/min

Max. coolant pressure: 160 bar

EQUIPMENT

- Hydraulically adjustable tailstock

- Manual tailstock adjustment for different tool positions Workpiece lengths

- Drill bushing holders and sealing housings from BOTEK

- Chip ejection directly into a collection container

- Integrated coolant system with paper belt filter

- Includes deep-hole drill bit and technical documentation

Transportation possible by standard truck

We make it easier for you to find: "schaffer 5050 z"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Schaffer 5050 Z (11,407)

Search Werktuigen now with more than 200,000 used machines:

Find out now

+49 201 857 86 180

+49 201 857 86 180

Create listing

*per listing / month