Used spring making machinery for sale (19)

Lyon

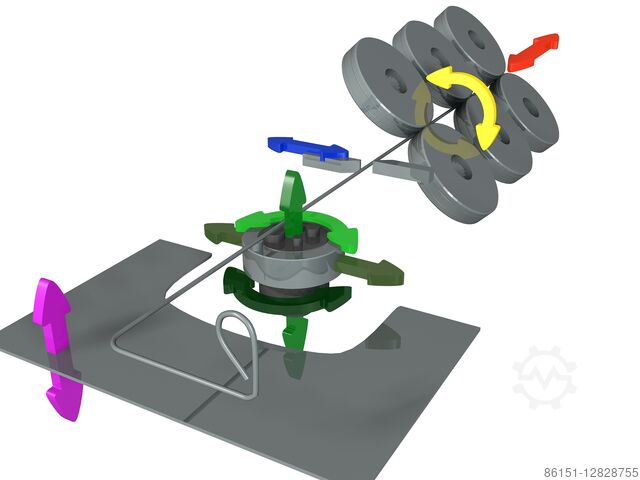

Lyon Cam-driven spring forming machine

MAX25TS-4A

Lyon

Lyon Spring manufacturing machines

MAXCR 35

Lyon

Lyon Spring manufacturing machines

MAXCT 25

+49 201 857 86 180

Lyon

Lyon Punching stamping bending former machine

BIHLERRM 40

Norderstedt

Norderstedt Production line for ZICK ZACK springs

WAFIOSSLF4/SLF4S

Discover more used machines

Lyon

Lyon CNC Compression spring machine

JD525

Lyon

Lyon Camless spring forming machine CNC

MAXCR 65

Lyon

Lyon Cam-driven spring forming machine

JD430

Lyon

Lyon Ø2.0mm/2-Axis compression spring machine

JD220

Lyon

Lyon Cam-driven spring forming machine

JD503

Lyon

Lyon Compression spring making machine

SchenkerFA 60 S; FA 30; FA 15 S; FA 6 S; 6 RU

Lyon

Lyon CNC torsion multislide spring former

EN-CNC502S 12

Lyon

Lyon Wire and strip bending machine

MAXWB60-8A

Lyon

Lyon Manual comp-ext-tor Spring Machine

Bielawa

Bielawa Spring coiling machine coiler

Schenker Moyer5S (FA 6S FA6S)

Bielawa

Bielawa Schenker FA 20S FA-20S spring coiler

SchenkerFA-20S

Bielawa

Bielawa Zugfeder extension spring machine

Asahi Seiki Extension spring with loopsNSF-10 Zugfeder

How can I spot good Spring making machinery?

Machine Condition

Inspect the machine carefully for any signs of wear, damage, or repairs. Machines in good condition should operate smoothly without excessive noise or vibrations. Ensure all components are intact and functional.

Brand and Manufacturer Reliability

Choose machines from reputable manufacturers known for their quality and durability. Research reviews and testimonials from other users to gauge the machine's reliability.

Technological Features

Look for machines that incorporate advanced technological features such as CNC controls, which allow for precise operations and flexibility in producing different types of springs. It's also beneficial if the machine offers various tools and adjustment mechanisms that help in fine-tuning the spring manufacturing process.

Performance and Output Quality

Check the machine’s performance by conducting a trial run, if possible. Observe the consistency and quality of the springs it produces. It’s crucial that the machine can consistently produce high-quality springs with minimal waste.

Service and Support

Confirm the availability of after-sales service and support. Reliable manufacturers should offer timely technical support, parts replacement, and repair services. This is important for maintaining the machinery in top working condition and for minimizing downtime.

Energy Efficiency

Evaluate the energy efficiency of the machinery. Energy-efficient machines not only reduce operating costs but also contribute to environmental sustainability.

Overall Value

Consider the machine's total cost of ownership, including initial costs, maintenance, spare parts, and energy consumption. Aim for a machine that offers the best balance of price, performance, and ongoing costs.

Machine Condition

Inspect the machine carefully for any signs of wear, damage, or repairs. Machines in good condition should operate smoothly without excessive noise or vibrations. Ensure all components are intact and functional.

Brand and Manufacturer Reliability

Choose machines from reputable manufacturers known for their quality and durability. Research reviews and testimonials from other users to gauge the machine's reliability.

Technological Features

Look for machines that incorporate advanced technological features such as CNC controls, which allow for precise operations and flexibility in producing different types of springs. It's also beneficial if the machine offers various tools and adjustment mechanisms that help in fine-tuning the spring manufacturing process.

Performance and Output Quality

Check the machine’s performance by conducting a trial run, if possible. Observe the consistency and quality of the springs it produces. It’s crucial that the machine can consistently produce high-quality springs with minimal waste.

Service and Support

Confirm the availability of after-sales service and support. Reliable manufacturers should offer timely technical support, parts replacement, and repair services. This is important for maintaining the machinery in top working condition and for minimizing downtime.

Energy Efficiency

Evaluate the energy efficiency of the machinery. Energy-efficient machines not only reduce operating costs but also contribute to environmental sustainability.

Overall Value

Consider the machine's total cost of ownership, including initial costs, maintenance, spare parts, and energy consumption. Aim for a machine that offers the best balance of price, performance, and ongoing costs.

Bielawa

Bielawa Torsion spring coiler FA-10T FA 10T FA10

SchenkerFA-10T

Bielawa

Bielawa Machines for the production of springs

ITAYAMCS 8E

Used spring making machinery (19)

Search Werktuigen now with more than 200,000 used machines:Browse through the most popular machine descriptions:

+49 201 857 86 180