Used Schaffer 9300 Z for sale (11,395)

Sort results

- Lowest price Highest price

- Latest listings Oldest listings

- Shortest distance Farthest distance

- Latest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Latest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Latest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation A to Z

- Designation

- designation Z to A

- Designation

- Model A to Z

- Model

- Model Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest running time

- Runtime

- Relevance

- Relevance

Listing

Germany

Germany

7,870 km

Vertical Machining Centre

DECKEL MAHODMU 65 monoBlock

Call

Condition: ready for operation (used), Year of construction: 2012, operating hours: 14,297 h, Control Unit

Brand Heidenhain

Duebvdidewgf Hvewst

Main Drive

Spindle speed range 18000

Number of axis 5

Movement

X-Axis Movement 735 mm

Y-Axis Movement 650 mm

Z-Axis Movement 560 mm

Additional Equipment

Magnetic plate

3D infrared probe

This 5-axis DECKEL MAHO DMU 65 monoBlock was manufactured in 2012. It features a vertical machining center with an 18000 rpm spindle and a 3D infrared probe. The machine dimensions are X: 735mm, Y: 650mm, Z: 560mm. Ideal for complex and precise machining tasks, the DECKEL MAHO DMU 65 monoBlock machine we have for sale. Contact us for further details regarding this vertical machining center.

Application Types

Milling

Listing

Matelica (MC)

Matelica (MC)

8,557 km

EDM Machines - Die sinking

CHARMILLESELERODA 400

Call

Condition: ready for operation (used), - USED - MANUAL DIE SINKING EDM MACHINE

X-AXIS TRAVEL: 400 mm

Y-AXIS TRAVEL: 250 mm

Z-AXIS TRAVEL: 200 mm

Duebvdewh Dhzjidwot

TANK SIZE: 800 x 500 x 400 mm

Listing

Emmelshausen

Emmelshausen

7,767 km

Wire erosion / EDM

AgieAgiecut Classic 2S

Call

Condition: used, Year of construction: 2004, Wire erosion / EDM

Travel distance X: 350 mm

Travel distanceY :250 mm

Travel distance z: 256 mm

max. workpiece size X: 750 mm

max. workpiece size Y: 550 mm

max. workpiece size Z: 250 mm

max. workpiece weight: 200 kg

Dobvdswf I Imsidwjut

submerged

cooling unit

The machine has been serviced annually by the manufacturer.

Find out now

+49 201 857 86 180

+49 201 857 86 180

Create listing

*per listing / month

Listing

Karben

Karben

7,833 km

Tool cutter

DECKELFP 1

Call

Condition: excellent (used), Year of construction: 1986, travel distance X-axis: 300 mm, travel distance Y-axis: 160 mm, travel distance Z-axis: 290 mm, Year of manufacture: 1986

Travel paths:

X = 300 mm

Y = 160 mm

Z = 290 mm

Equipment:

Standard accessories

Vertical milling head, SK 40/20x2

Fixed angle table 210 x 600 mm, NEW!

Retrofitted safety device for milling spindle,

Dobvswgafysdidwjut

electrically protected, NEW!

Active digital display (TNC113), 3 axes

Coolant system

Machine light

Machine feet

Documentation

Condition: Good, mechanics and control system workshop-tested

Listing

Zuchwil

Zuchwil

7,953 km

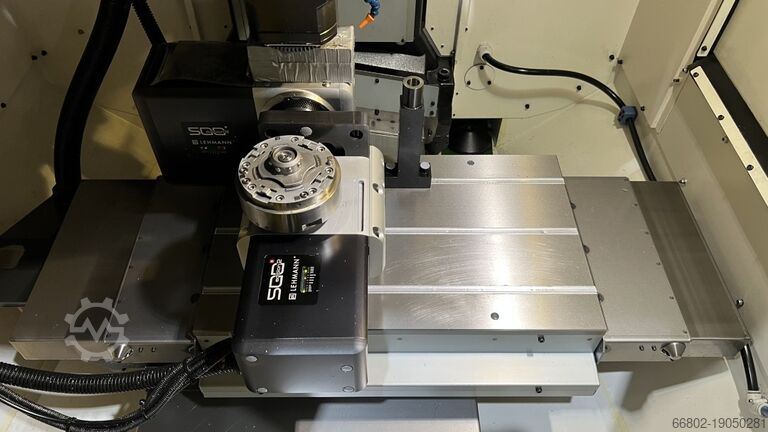

Machining center

FANUCα-D21MiA5 CNC

Call

Condition: excellent (used), Year of construction: 2014, operating hours: 10,000 h, Fanuc α-D21MiA5 CNC Machining Center

Spindle speed: 24,000 rpm (High Power Version)

X-axis travel: 500 mm

Y-axis travel: 400 mm

Z-axis travel: 330 mm

4th and 5th axes: Yes

Rapid traverse: X-axis: 54 m/min

Y-axis: 54 m/min

Z-axis: 54 m/min

Worktable load capacity: 300 kg

Tool changer load capacity: 23 kg

Max. tool weight: 2 kg

Tool diameter:

150 – 12,000 rpm: 80 mm

12,000 – 15,000 rpm: 60 mm

15,000 – 20,000 rpm: 45 mm

20,000 – 24,000 rpm 40 mm

SCOPE OF OFFER

INCLUDES (list is not exhaustive):

Fanuc α-D21MiA5 CNC machining center

Lehmann dividing head 4th and 5th axis

Tool holder set

Renishaw touch probe

Fire extinguishing system

Coolant tank / high-pressure pump

Absolent oil mist separator

Duebvdidewgn Hlowjt

Operating documentation

Exact scope of offer as per photo gallery

No liability is assumed for the accuracy, completeness, or timeliness of the information.

Listing

Wijchen

Wijchen

7,560 km

Drilling machine

GSP2-Column Jig Boring 2-Column

Call

Condition: used, Price: On request

- Documentation available: No

- Control: Conventional

- Drilling depth: 150mm

- Model: ördinatenboor

- Digital readout: Yes

- Table width: 1500mm

- Table length: 2200mm

- Travel X: 2500mm

- Travel Y: 1400mm

- Spindle diameter: 100mm

- Travel Z: 1000mm

- Number of axes: 3

Financial information

VAT: The price shown is exclusive of VAT

VAT/margin: VAT deductible for entrepreneurs

Delivery and trade-in always possible for everything in the industrial sectors

Dusbvdidowfpbbowet

Bram van Summeren

Listing

Germany

Germany

7,870 km

CNC Milling Machine

HERMLEC800 U

Call

Condition: ready for operation (used), Year of construction: 1998, operating hours: 10,682 h, General Data

Measurements width 2.21 m

Measurements depth 2.7 m

Measurements height 2.93m

Machine weight 7500kg

Control Unit

Brand SIEMENS

Main Drive

Spindle speed range 20-8000 min-1

Tool taper SK 40

Number of axis 5

Movement

X-Axis Movement 800

Y-Axis Movement 600

Z-Axis Movement 500

Tools

Type of tool holder SK 40

Dusbvdidswgf A Dowot

Additional Equipment

Extended tool magazine

30 tool positions

not included in delivery: fixture shown in pictures is not for sale

This 5-axis HERMLE C800 U was manufactured in 1998 and features a Siemens control system and an extended tool magazine. With a SK 40 tool holder, it has driven 91886 hours and the spindle has operated for 10682 hours. If you are looking to get high quality milling capabilities consider the HERMLE C800 U machine we have for sale. Contact us for more information.

Application Types

Milling

Listing

Matelica (MC)

Matelica (MC)

8,557 km

Lathes

CITIZENC32-VIII

Call

Year of construction: 2005, Condition: ready for operation (used), - USED - 6-AXIS SLIDING HEADSTOCK LATHE WITH BAR FEEDER

MAX TURNING LENGTH: 320 mm

MAX TURNING DIAMETER: 32 mm

SPINDLE: 200-8000 rpm; 3,7 - 7,5 kW

COUNTER SPINDLE: 200-7000 rpm; 1,5 - 2,7 kW

X1-AXIS TRAVEL: 108 mm

X2-AXIS TRAVEL: 228 mm

Y1-AXIS TRAVEL: 275 mm

Z1-AXIS TRAVEL: 325 mm

Z2-AXIS TRAVEL: 130 mm

Z3-AXIS TRAVEL: 410 mm

RAPID FEEDS X-Y-Z: 20 m/min

DRIVEN TURRET HEAD: 8 POS; 200 - 5000 rpm

CONTROL UNIT: CINCOM SYSTEM M6D

Duobvdiowh Dhhjdwjt

BAR FEEDER: IEMCA Mod. BOSS 332 EVOLUTION

WEIGHT: 2850 Kg

ACCESSORIES: PARTS CATCHER ;

SWARF CONVEYOR

Listing

Siegen

Siegen

7,752 km

SORALUCE TR-25 Including installation

SoraluceTR-25

Call

Condition: reconditioned (used), Year of construction: 2002, Functionality: fully functional, travel distance X-axis: 2,500 mm, travel distance Y-axis: 1,600 mm, travel distance Z-axis: 1,200 mm, rapid traverse X-axis: 15 m/min, rapid traverse Y-axis: 15 m/min, rapid traverse Z-axis: 15 m/min, feed rate X-axis: 12 m/min, feed rate Y-axis: 12 m/min, feed rate Z-axis: 12 m/min, spindle speed (max.): 3,000 rpm, table width: 1,200 mm, tool mount: 50 mm, power: 0.028 kW (0.04 HP), SORALUCE TR-25 included installation and commissioning

Year of manufacturing: 2002

Capacities / travel:

Axis (X): mm 2.500

Vertical (Y): mm 1.600

Ram (Z): mm 1.200

Table size:

Length: mm 2.860

Width: mm 1.200

Painting: RAL 5005 and RAL 7035

Tool taper: ISO 50, DIN 69871 Form AD

Main Spindle Drive:

Power: 100 % ED KW28

Spindle speed range:

Spindle speed: rpm-1 20-3.000

Feeds:

Dsbvdsrp H D Toidwsut

X-, Y- und Z-Axis mm/min 2 – 12.000

Max. rapid traverse speed:

X-, Y- und Z-Axis mm/min 15.000

Weight: kg 22.200

Heidenhain 426

Heidenhain CNC control 426M with digital drive technology,

electronic handwheel HR410

Automatic Milling Head, Diagonal H26

Automatically indexing Soraluce "Diagonal" milling head, type H26 including a long spindle for internal coolant supply. 2.5° division in both joints and speeds up to 3000 rpm. Clamping via Hirth serration in both joints. Repeatability of +/-3 sec. or 0.002mm. FAG spindle bearing with steel balls. Includes air lock.

Chip Conveyor

Automatic Tool changer:

Maximum Tool Diameter: 125 mm

Max. Tool Diameter with Adjacent Slots Free: 250 mm

Maximum Tool Length: 400 mm

Maximum Tool Weight: 20 kg

Number of Magazine Slots: 40

Coolant lubrication system internally cooling

3D thermal expansion compensation

Splash guard

Our product line: RepairFIT

RepairFIT is our proven offer for a profitable entry into our product lines. The machines available in this line have been procured by us following a strict selection process and have undergone a thorough examination (Deep-Dive-Check). After intensive cleaning, any detected and obvious defects or errors have been professionally repaired by our expert service team.

What does this mean for you?

A RepairFIT offer is ideal for you if you're looking for a used machine while also wanting guaranteed process safety. With this option, you receive a high-quality CNC milling machine that is immediately ready for error-free operation. With our professional service technicians, we implement the commissioning in your premises in the shortest possible time. You can start production right away. This is a clear difference from an ordinary used machine purchase. This solution offers you guaranteed process and planning reliability at an attractive fixed price

Project Execution:

Benefit from our turnkey project execution, which is included in all lines: Our team of experts provides comprehensive support in optimally determining the machine's location, creating a professional layout, and fully integrating it into your manufacturing process. We ensure that your CNC milling machine is expertly installed, commissioned, and precisely aligned according to the manufacturer's specifications! All from a single source, in the end, simply a process-reliable machine that does what it's supposed to do.

Listing

Zevenbergen

Zevenbergen

7,503 km

CNC Lathe with Y-axis, driven tools an 2

Mori SeikiNL 2500 SY / 1250

Call

Condition: used, Year of construction: 2008, turning diameter: 275 mm, spindle bore: 80 mm, spindle speed (max.): 4,000 rpm, travel distance X-axis: 260 mm, travel distance Z-axis: 1,345 mm, total height: 2,232 mm, total length: 4,339 mm, total width: 2,232 mm, overall weight: 7,600 kg, Equipment: documentation/manual, CNC Lathe with Y-axis, driven tools an 2nd spindle

CNC Control MSX-850-lll (mitsubishi 720 BM)

Turning diameter 275 / 366 mm

Spindle bore diameter 80 mm

Spindle speed 4000 R/min

Spindle motor 18.5/15 Kw

Movement X-axis 260 mm

Movement Y-axis +50 / -50 mm

Movement Z-axis 1345 mm

Dobvdswfdz Noidwsut

Movement W-axis (subspindle to mainspindle) 1275 mm

Min indexing C-axis main spindle 0,001 °

Number of tools on turret 12x

Number of driven tools 12 x

Tool Taper BMT

Bar feeder LNS Quick Load Servo lll

Spindle motor driven tools 6000 R/min

If you have any questions concerning the machine, please do not hesitate to contact us by phone or e-mail.

Feel free to view our other advertisements for a complete overview of our stock.

Listing

Zuchwil

Zuchwil

7,953 km

Double spindle machining center

CHIRONDZ 08 FX

Call

Condition: excellent (used), Year of construction: 2014, operating hours: 13,800 h, Chiron DZ 08 FX Twin-Spindle Machining Center

Djbvdjwgn D Reidwsut

X-axis travel: 450 mm

Y-axis travel: 270 mm

Z-axis travel: 310 mm

Spindle: Speed: 18,000 rpm

Clamping set: HSK-A40

Lubrication: Grease

Swivel axis: Swivel angle: +-100°

Repeatability: +- 5"

Position measuring system: ECN 225

Max. transmittable torque: 440 Nm

Speed: 100 rpm

Holding torque: 410 Nm

NC rotary table: Faceplate diameter: 245 mm

Thread and bore pitch: M16 x 15

Repeatability: 5"

Position measuring system: ECN 225

Max. transmittable torque: 180 Nm

Holding torque: 410 Nm

Max. load capacity: 80 kg

Speed: 200 rpm

Weight: 4500 kg

SCOPE OF OFFER

INCLUDES (list is not exhaustive):

Chiron twin-spindle machining center

Absolent oil mist separator

High-pressure system

Chip conveyor

Oil cooler

Measuring probe

Set of HSK-40 tool holders

Complete operating documentation

Exact scope of offer as shown in the photo gallery

No liability is assumed for the accuracy, completeness, or timeliness of the information.

Listing

Wijchen

Wijchen

7,560 km

Cylinder grinder Tacchella 350x1000-Ex+in

Tacchella350x1000-Ex+in -Ex+In

Call

Condition: used, Price: On request

- Documentation available: No

- Control: Conventional

- Motor power: 9.6kW

- Travel Z: 0mm

- Center distance: 1000mm

- Model: inderslijper intern & extern

- Travel X: 1000mm

- Center height: 180mm

- Grinding diameter: 350mm

- Table length: 1700mm

- Max. spindle speed: 1450rpm

- Table width: 175mm

- Min. spindle speed: 400rpm

Duebvowfn T Aedidwet

Financial information

VAT: The price shown is exclusive of VAT

VAT/margin: VAT deductible for entrepreneurs

Delivery and trade-in always possible for everything in the industrial sectors

Bram van Summeren

Listing

Hungary

Hungary

8,662 km

Universal Machining Centre

DMG MORIHSC 105

Call

Condition: ready for operation (used), Year of construction: 2021, Control Unit

Brand HEIDENHAIN

Model iTNC530 HSCI

Dusbvdiswiadbsdwjt

Main Drive

Spindle speed range 20-28000 rpm

Spindle motor power 55/43.5 kW (40/100%DC)

Movement

X-Axis Movement 1050

Y-Axis Movement 800

Z-Axis Movement 560

Additional Equipment

Tool Taper: HSK-A63 DIN 69893 / Tool Magazine: 30-position disk tool magazine, 60-position pickup chain type

Scraper Belt Chip Conveyor and Machine Bed Flushing / Separate Water Treatment Unit: 980-liter tank and paper filter / Pump: 40 bar / 23 l/min for internal cooling through spindle / Extended Chip Flushing / Rotating Inspection Window / Manual Coolant Flushing Gun / Internal Compressed Air Cooling: Through spindle / EROWA Pallet Handling System Preparation

Documentation: English, Hungarian / Display Text: German/Hungarian / Screen Text: German/Hungarian

DMG MORI Monitoring: D-ME406* DMG MORI Messenger V4 / DMG MORI Software Solutions: DMG MORI Service Agent, DMG MORI NETSERVICE, DMG MORI IoTconnector

This 5-axis DMG MORI HSC 105 universal machining center was manufactured in 2021. It offers advanced capabilities for precision machining. Consider the opportunity to buy this DMG MORI HSC 105 universal machining center. Contact us for more information.

Application Types

Milling

Listing

Matelica (MC)

Matelica (MC)

8,557 km

Machining Centres - Vertical

DMG MORICMX 1100 V

Call

Condition: ready for operation (used), Year of construction: 2018, - USED - 3-AXIS VERTICAL MACHINING CENTRE

X-AXIS TRAVEL: 1100 mm

Y-AXIS TRAVEL: 560 mm

Duobvdjwh Dg Roidwot

Z-AXIS TRAVEL: 510 mm

DISTANCE SPINDLE NOSE-TABLE: 120-630 mm

RAPID FEEDS X-Y-Z: 30 m/min

SPINDLE: 20 - 12000 rpm; 9 - 13 kW; ISO 40 - DIN

TABLE SIZE: 1400 x 560 mm

MAX ADMITTED LOAD: 1000 Kg

HIGH PRESSURE COOLANT: 12 Bar

TOOL MAGAZINE: CHAIN-TYPE ; 30 POS

CONTROL UNIT: HEIDENHAIN TNC 620

WEIGHT: 5830 Kg

OVERALL DIMENSIONS: 4028 x 2750 x 2950 mm

ACCESSORIES: SWARF CONVEYOR ;

PORTABLE HANDWHEEL

NOTE: WITH No 30 TOOLS-HOLDERS ISO 40

Listing

Siegen

Siegen

7,752 km

Bed type milling machine

MTEBF 3200

Call

Condition: reconditioned (used), Year of construction: 2005, Functionality: fully functional, travel distance X-axis: 3,000 mm, travel distance Y-axis: 1,000 mm, travel distance Z-axis: 1,000 mm, rapid traverse X-axis: 10 m/min, rapid traverse Y-axis: 10 m/min, rapid traverse Z-axis: 10 m/min, feed rate X-axis: 4 m/min, feed rate Y-axis: 4 m/min, feed rate Z-axis: 4 m/min, table width: 1,000 mm, table load: 5,000 kg, table length: 3,000 mm, overall weight: 16,500 kg, year of last overhaul: 2024, RepairFIT by Dornhöfer

The Difference.

Including installation and commissioning!

MAIN TECHNICAL DATA

Year of manufacture: 2005

Capacities / Travel: Longitudinal (X): 3,000 mm

Vertical (Z): 1,000 mm

Transverse (Y): 1,000 mm

Table size: Length: 3,200 mm

Width: 1,000 mm

Number of T-slots on the table surface:

7

T-slot width: 22H12 mm

Max. table load: 5 t/m²

Paint finish: RAL 5010 and RAL 9002

Dujbeuq Episvdidwjt

Tool holder: ISO 50, DIN 69871 AD

Pull stud: DIN 69872 Form A

Main drive:

Drive power: 100% duty cycle KW30

Spindle speed range:

Spindle speed: min-1 20-3,000

Speed control: via gear box

Feed rates: X, Y, and Z axes mm/min 4,000

Max.

Rapid traverse speed: X, Y, and Z axes mm/min 10,000

Weight: approx. 16,500 kg

BASIC MACHINE EQUIPMENT:

HEIDENHAIN iTNC 530 HSCI

Manual diagonal head

Chip conveyor

Cooling lubricant system with 20 bar & (IKZ)

RepairFIT is our proven offering for a profitable entry into our product lines.

The machines available in this line are procured by us following a rigorous selection process and subjected to a thorough inspection (deep dive check). After intensive cleaning, any obvious defects and faults identified were professionally repaired by our expert service team.

Listing

Dieburg

Dieburg

7,859 km

5-axis vertical machining center

BROTHER TC-32 BM QT

Call

Condition: excellent (used), Year of construction: 2007, CNC Vertical Machining Center

BROTHER TC-32 BM QT

2007

5-Axis

Technical Specifications:

Travels

X-axis: 550 mm

Duobvdidowgaixewjt

Y-axis: 400 mm

Z-axis: 415 mm

Worktable: 550 x 400 mm

Table load: 200 kg

Max. spindle speed: 12,000 RPM

2 pallets

0/180°

Listing

7 Fraser Rd, Erith DA8 1PP, UK

7 Fraser Rd, Erith DA8 1PP, UK

7,247 km

Center lathe

Used Mazak Integrex i100S CNC Multitasking Turning Centre 850mm Bed

Call

Condition: excellent (used), Year of construction: 2017, Functionality: fully functional, machine/vehicle number: 285827, MACHINE SPECIFICATION

Maximum swing 530mm

Swing over cross slide 530mm

Maximum machining diameter (upper turret) 500mm

Bar work capability main spindle 51mm

Bar work capability secondary spindle 51mm

Maximum machining length 854mm

Maximum support weight main spindle chuck work 150Kg

Maximum support weight main spindle shaft work 150Kg

Main Spindle

Rotating speed maximum 6000 min-1

Rotating speed minimum 35 min-1

Acceleration and deceleration time 4.0 s

Through hole diameter 61mm

Motor output (continuous rating) 7.5kW

MACHINE SPECIFICATION Cont’d

Secondary Spindle

Rotating speed maximum 6000 min-1

Rotating speed minimum 35 min-1

Milling head

Type Single Spindle with ATC unit

Tool shank type CAPTO C6

Tool size (OD turning) 20mm

Tool size (ID turning) 32mm

Tool size (milling tool max. diameter) 130mm

Tool size (milling tool max. diameter) 250mm

90° indexing time 0.5 s

Feed Axes

Rapid feed rate X 40000mm/min

Rapid feed rate Z 40000mm/min

Rapid feed rate Y 40000mm/min

Rapid feed rate W 30000mm/min

Movement stroke X 450mm

Movement stroke Z 904mm

Movement stroke Y 210mm

Movement stroke W 903mm

Others

Coolant tank capacity 210L

Power requirements (continuous) 36.71 kVA

Air pressure 0.5

Total air capacity 230 I/min

Machine dimensions

Height of centers 1250mm

Length (excluding feed and swarf management system) 2495mm

Width (excluding Rotac Rack unloading system) 3030mm

Height 2500mm

Weight 10,400Kg

Auto tool changer & magazine

Type of tool magazine 36

MACHINE SPECIFICATION Cont’d

Maximum tool diameter (with adjacent tool) 90mm

Maximum tool diameter (no adjacent too) 130mm

Maximum tool weight 5Kg

Maximum tool length 250mm

GENERAL MACHINE OPTIONS

AS092 Automatic power on/off and warm up

AS250 ATC auto recovery

CO032 Chuck airblast (2nd spindle)

BY NC command

EL110 Power transformer for European market

Dusbvewhx I Aodidwot

MM007 Number display magazine panel (n/a with tool ID)

MO555 Coolers for ball screw (XZ axis)

MO575 Roller guide

NO823 USB interface (1 port)

SD116 Intelligent performance spindle A

SD120 One set of adjusting tools

SD130 Foundation kit (plates)

SI039 C axis 0.0001° increments

Listing

Metzingen

Metzingen

7,973 km

Universal Milling Machine

MIKRONWF 2/3S

Call

Condition: used, Year of construction: 1982, x-travel 400 mm

y-travel 400 mm

Duobvdiju U Sabjdwet

z-travel 380 mm

total power requirement 2,6 kW

weight of the machine ca. 1,5t t

Listing

Niederlangen

Niederlangen

7,585 km

Milling Machining Centers 5 Axis

HEDELIUSTiltenta 7 Magnum

Call

Condition: used, Year of construction: 2018, x-travel 3200 / 2630 mm

y-travel 750 mm

z-travel 695 / 800 mm

Duebewfqqkevdidwot

Control Heidenhain TNC 640

swivelling range -98 bis 98 Grad

rotary table dia. 750 mm

total power requirement 22 kW

weight of the machine ca. 16 t

Hedelius Fahrständer- Bearbeitungszentrum Tiltenta 7 Magnum

mit stufenlos schwenkbarer Hauptspindel, 5-Achsen CNC- Steuerung Heidenhain

TNC 640, 22,0 kW/117 Nm Hauptspindelantrieb 50- 12000 1/min, 50- fach

Werkzeugmagazin und im feststehenden Maschinentisch intregiertem NC Rundtisch.

Listing

Siegen

Siegen

7,752 km

Bed type milling machine

SoraluceTA-D25

Call

Condition: reconditioned (used), Year of construction: 2008, Functionality: fully functional, travel distance X-axis: 2,500 mm, travel distance Y-axis: 1,250 mm, travel distance Z-axis: 1,000 mm, rapid traverse X-axis: 25,000 m/min, rapid traverse Y-axis: 25,000 m/min, year of last overhaul: 2025, RepairFIT by Dornhöfer

The Difference.

Including installation and commissioning!

Technical details of the machine:

Year of manufacture: 2008

Control: Heidenhain iTNC 530

Travel range: X-axis (mm) 2,500

Y-axis (mm) 1,250

Z-axis (mm) 1,000

Rotary table size: Length (mm) 1,000

Width (mm) 1,000

Spindle speed range: 15,000 rpm

Feed rates: X, Y & Z axes (mm/min): 10 - 10,000

Max. rapid traverse speed X, Y & Z axes (mm/min): 25,000

Milling head: Automatic milling head, vertical

Tool holder: HSK 63 A

Main spindle drive power: 100% duty cycle KW25

- Chip conveyor

- Cooling lubricant system

- 3D thermal expansion compensation

- Portable electronic handwheel Heidenhain HR 410 with 3m spiral cable

- INA RUE 45 linear guideway system on all linear axes with central lubrication

Duebvjv Rw Uuodidwjt

- Complete splash guard enclosure

RepairFIT is our proven offering for a profitable entry into our product lines.

The machines available in this line are procured by us following a rigorous selection process and subjected to a thorough inspection (deep dive check). After intensive cleaning, any obvious defects and faults identified are professionally repaired by our expert service team.

Listing

Siegen

Siegen

7,752 km

Travelling column milling machine

MTEFBF-M 8000

Call

Condition: reconditioned (used), Year of construction: 2015, Functionality: fully functional, travel distance X-axis: 8,000 mm, travel distance Y-axis: 3,000 mm, travel distance Z-axis: 1,500 mm, feed rate X-axis: 15,000 m/min, feed rate Y-axis: 15,000 m/min, feed rate Z-axis: 15,000 m/min, spindle speed (max.): 6,000 rpm, coolant supply: 20 bar, RepaitFIT+ by Dornhöfer

The difference.

Including installation and commissioning!

MAIN TECHNICAL DATA

Year of manufacture: 2015

Capacities / Travel: Longitudinal (X): 8,000 mm

Vertical (Y): 3,000 mm

Transverse (Z): 1,500 mm

Main spindle drive:

Motor / Make: Siemens main spindle drive type: 1PH7

Maximum drive power: 41 kW

Maximum torque: 1,055 Nm

Speed control / Gearbox: 3-stage (oil-cooled) with automatic switching

Spindle speeds 6,000 rpm:

Low range: 0-918 rpm

Medium range: 919-2,404 rpm

High range: 2,405-6,000 rpm

Axis drives / axis feeds:

Axis drive motors: SIEMENS (digital) Drives)

Maximum rapid traverse: (X/Y/Z axis) 25,000 mm/min

Maximum working feed: (X/Y/Z axis) 15,000 mm/min

Maximum feed force: (X-axis) 35,000 N

(Y/Z axis) 35,000 N

Drive systems:

X-axis (longitudinal) pinion/rack (Atlanta brand)

Y-axis (vertical) ball screw (preloaded) Ø 63x20

Z-axis (transverse) ball screw (preloaded) Ø 50x20

Machine weight:

Weight FBF-M 8000 kg 41,000

without clamping table/plate array

Connected load: KVA approx. 60

Paint finish: sky blue RAL 5015 / light gray RAL 7035

Tool holder: ISO 50, DIN 69871 AD

Pull stud: DIN 69872 Form A

HEIDENHAIN iTNC 530 HSCI

Automatic MTE Diagonal milling head

Automatic tool changer

Cooling lubricant system with 20 bar & (internal coolant supply)

Frequency control for coolant pump

Air cooling through the spindle

Djbvdidjv R Hqrewjut

Operator platform with height adjustment of 2,300 mm and transverse travel of 800 mm

Heidenhain HR 550 FS wireless handwheel

Special operating mode (operating mode 4)

RepairFIT+ – what does that mean?

With RepairFIT+, we offer you a profitable and safe entry into our product lines. Our machines undergo a rigorous selection process, undergo a comprehensive deep-dive check, and are thoroughly cleaned by our experts. All identified defects, both technical and visual, are professionally repaired so that the machine is presented in perfect condition.

Trust Seal

Dealers certified through Werktuigen

Listing

Siegen

Siegen

7,752 km

Machining center

SoraluceFL-4000

Call

Condition: reconditioned (used), Year of construction: 2007, travel distance X-axis: 3,500 mm, travel distance Y-axis: 1,400 mm, travel distance Z-axis: 1,000 mm, table width: 1,500 mm, table length: 3,750 mm, 100% Retrofit by Dornhöfer

The Difference.

Including installation and commissioning!

Year of manufacture: 2007

Control: Heidenhain TNC 640

Travel: X-axis (mm) 3,500

Y-axis (mm) 1,400

Z-axis (mm) 1,000

Spindle speed range: 20–3,000 rpm

Milling head: Automatic milling head, diagonal H26 2.5° x 2.5°

Tool holder: ISO 50, DIN 69872 AD

Main spindle drive power: 28 kW

Maximum spindle speed: 3,000

-Chip conveyor

-Cooling lubricant system

-3D thermal expansion compensation

Dsbjv R Hxpjvdidwout

-Automatic tool changer with 60 magazine positions

-Movable control panel

-Complete splash guard (fully enclosed)

-NC rotary table 1,000 mm x 1000mm

100% RetroFIT – our core business! For us, it means offering a machine that can only be compared to a new product, but also offers you many other advantages:

Latest CNC control technology with proven machine stability

Significant CO₂ savings compared to a new machine

Shorter delivery times

Often savings on expensive foundation costs

Significantly lower investment costs

All mechanical components (e.g., ball screws, guides, roller bearings, etc.) have been

renewed. Our designers designed the entire electrical peripherals (such as the most modern drive, control, and regulation technology) using the most efficient technologies. This was implemented using new cabling and a completely new control cabinet, as well as the latest Heidenhain control system with a wide range of innovative options.

The completely new and innovative hydraulic concept meets the most modern requirements and achieves maximum efficiency.

The machine's visual appearance is in no way inferior to that of a new machine thanks to its refurbishment: The entire machine was first disassembled down to every screw, sanded, primed, and then painted with a robust 2K EP paint.

We have equipped the machine with a safety concept that is individually tailored to the needs of the operator. We offer the highest level of safety, flexibility, and ergonomics.

You get a state-of-the-art machine combined with significant CO₂ savings.

Listing

Siegen

Siegen

7,752 km

Bed type milling machine

SORALUCETA-A25

Call

Condition: refurbished (used), Year of construction: 2007, Functionality: fully functional, travel distance X-axis: 2,500 mm, travel distance Y-axis: 1,250 mm, travel distance Z-axis: 1,200 mm, rapid traverse X-axis: 25 m/min, rapid traverse Y-axis: 25 m/min, rapid traverse Z-axis: 25 m/min, feed rate X-axis: 10 m/min, feed rate Y-axis: 10 m/min, feed rate Z-axis: 10 m/min, spindle speed (max.): 4,000 rpm, spindle speed (min.): 20 rpm, table width: 850 mm, table load: 5,000 kg, table length: 2,700 mm, overall weight: 15,500 kg, year of last overhaul: 2024, RefurbishmentPLUS by Dornhöfer

The difference.

Including installation and commissioning!

MAIN TECHNICAL DATA

Year of manufacture: 2007

Capacities / Travel:

Longitudinal (X): 2,500 mm

Vertical (Y): 1,250 mm

Cross (Z): 1,200 mm

Table size:

Length: 2,700 mm

Width: 850 mm

Number of T-slots on the table surface:

6

T-slot width: 22H12 mm

Reference slot: 22H8 mm

Distance between slots: 140 mm

Max. table load: 5 t/m²

Paint finish:

RAL 5011 (steel blue) and

RAL 7035 (light gray)

Tool holder: ISO 50, DIN 69871 AD

Pull stud: DIN 69872 form A

Main drive:

Drive power: 100% duty cycle KW24

Spindle speed range:

Spindle speed: 20-4,000 rpm

Torque: 479 Nm

Feed rates: X, Y, and Z axes mm/min

10-10,000

Max. rapid traverse speed:

X, Y, and Z axes mm/min 25,000

Weight: approx. 15,500 kg

BASIC MACHINE EQUIPMENT:

Heidenhain iTNC 530 HSCI

Automatic milling head, diagonal H200

Chip conveyor

Coolant system

STANDARD EQUIPMENT:

- Portable electronic handwheel HR 510 with 3m spiral cable

- Hydraulic counterbalance acting directly on the vertical slide

- 3D thermal expansion compensation for Heidenhain CNC contouring controls

- Complete splash guard enclosure consisting of two front doors and one rear door for operating the machine from the front and rear.

All doors are equipped with viewing windows.

- Heidenhain AC drive motors in all axes with diagonal drive technology

- INA RUE 45 linear guideway system in all axes with central lubrication

- Ball screws (IT5) in all axes

- Heidenhain direct linear measuring system in all axes

- Telescopic covers for the X-axis guideways

- Automatic cyclic lubrication for all axes and motion components

- Work area lighting

Refurbishment+ – what does that mean?

The RefurbishmentPLUS line offers you a machine that has been uncompromisingly restored to its original technical and visual condition.

All assemblies have been completely disassembled, repainted, and rebuilt with new, original spare parts.

Cables, hydraulics, guides, spindles, rolling bearings – everything new!

Duebvdioun Nnqjdwst

Listing

Siegen

Siegen

7,752 km

Travelling column milling machine

SoraluceFR16000

Call

Condition: reconditioned (used), Year of construction: 2002, travel distance X-axis: 16,000 mm, travel distance Y-axis: 3,200 mm, travel distance Z-axis: 1,500 mm, rapid traverse X-axis: 15,000 m/min, rapid traverse Y-axis: 15,000 m/min, rapid traverse Z-axis: 15,000 m/min, spindle speed (max.): 4,000 rpm, spindle speed (min.): 20 rpm, 100% Retrofit by Dornhöfer

The Difference.

Including installation and commissioning!

Year of manufacture: 2002

Control: Heidenhain TNC 640 / TNC 7

Travel: X-axis (mm) 16,000* (see below)

Y-axis (mm) 3,200

Z-axis (mm) 1,500

Djbvdjv S Upfjidwout

Spindle speed range: 20–4,000 rpm

Feed rates: X, Y & Z axes (mm/min): 2–12,000

Max. rapid traverse speed X, Y & Z axes (mm/min): 15,000

Milling head: Automatic milling head, orthogonal H10, 1° pitch

Tool holder: ISO 50, DIN 69871 AD

Main spindle drive power: 100% duty cycle KW37

- Automatic tool changer with 60 magazine positions

- Coolant system with 20 bar & (IKZ)

- Chip conveyor, floor ejection

- Ergonomic operator platform

- Hazardous area protection

- 3D thermal expansion compensation

- INA linear guides

*Adaptive X-axis length: We supply the machine bed in the length you require, up to a maximum of 16,000 mm.

100% RetroFIT – our core business! For us, it means offering a machine

that can only be compared to a new product, but

also offers you many other advantages:

Latest CNC control technology with proven machine stability

Significant CO₂ savings compared to a new machine

Shorter delivery times

Often savings on complex foundation costs

Significantly lower investment costs

All mechanical components (e.g., ball screws, guides, rolling bearings, etc.) have been

renewed. Our designers designed the entire electrical peripherals (such as the most modern drive, control, and regulation technology) using the most efficient technologies. This was implemented using new cabling and a completely new control cabinet, as well as the latest Heidenhain control system with a wide range of innovative options.

The completely new and innovative hydraulic concept meets the most modern requirements and achieves maximum efficiency.

The machine's visual appearance is in no way inferior to a new machine thanks to its refurbishment: The entire machine was first disassembled down to every screw, sanded, primed, and then painted with a robust 2K EP paint.

We equipped the machine with a safety concept that is individually tailored to the needs of the operator. We offer the highest level of safety, flexibility, and ergonomics.

You receive a state-of-the-art machine combined with significant CO₂ savings.

Listing

Siegen

Siegen

7,752 km

Travelling column milling machine

MTEFBF-M 10000

Call

Condition: reconditioned (used), Year of construction: 2015, Functionality: fully functional, travel distance X-axis: 10,000 mm, travel distance Y-axis: 3,000 mm, travel distance Z-axis: 1,500 mm, rapid traverse X-axis: 25,000 m/min, rapid traverse Y-axis: 25,000 m/min, rapid traverse Z-axis: 25,000 m/min, spindle speed (max.): 4,000 rpm, RepaitFIT+ by Dornhöfer

The difference.

Including installation and commissioning!

MAIN TECHNICAL DATA

Year of manufacture: 2015

Capacities / Travel: Longitudinal (X): 10,000 mm

Vertical (Y): 3,000 mm

Transverse (Z): 1,500 mm

Paint finish: Graphite gray RAL 7024 / Agate gray RAL 7038

Tool holder: ISO 50, DIN 69871 AD

Pull stud: DIN 69872 Form A

Taper: DIN 69871

Main drive:

Motor / Make: Siemens Main spindle drive Tap: 1PH7

Maximum drive power: From 198 rpm 100% duty cycle KW41

Maximum torque: Constant up to 198 rpm 100% duty cycle 1920 Nm

Speed control / Gearbox: 3-stage (oil-cooled) With automatic Switching

Spindle speeds 4000 rpm: low range rpm 0 - 516

medium range rpm 460 - 1,288

high range rpm 1,200 - 4,000

Axis drives/axis feeds:

Axis drive motors:

Maximum rapid traverse: (X/Y/Z axis) 25,000 mm/min

Maximum working feed: (X/Y/Z axis) 15,000 mm/min

Maximum feed force: (X-axis) 35,000 N

(Y/Z axis) 32,000 N

Axis drive systems:

X-axis (longitudinal) pinion/rack (Atlanta brand)

Y-axis (vertical) ball screw (preloaded) Ø 63 x 20

Z-axis (transverse) Ball screw (preloaded) Ø 50 x 20

Weight: (without clamping table/plate area) approx. 49,500 kg

Connection cable: approx. 60 kVA

Innotrol HBG wireless handwheel

Automatic tool changer with 60 magazine positions

BIG Plus tool spindle

Operator platform with height adjustment of 1800 mm and transverse adjustment of 800 mm

Djbov R Hwrevdidweut

Interface for adapter milling heads

RepairFIT+ – what does it mean?

With RepairFIT+, we offer you a profitable and safe entry into our product lines. Our machines undergo a rigorous selection process, undergo a comprehensive deep-dive inspection, and are thoroughly cleaned by our experts. All identified defects, both technical and cosmetic, are professionally repaired so that the machine is presented in perfect condition.

We make it easier for you to find: "schaffer 9300 z"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Schaffer 9300 Z (11,395)

Search Werktuigen now with more than 200,000 used machines:

Find out now

+49 201 857 86 180

+49 201 857 86 180

Create listing

*per listing / month